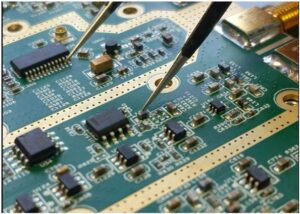

If you have ever built electronics, you know that getting from design to a finished product has a lot of moving parts. Whether it is sourcing components, fabricating the boards, assembling them, testing them, and finally getting them shipped, it is a lot of juggling. And that’s where turnkey PCB assembly comes into the picture.

So, to start with, what is turnkey PCB assembly? In simple terms, it’s a one-stop service where a single provider will manage everything from sourcing parts to delivering a fully assembled printed circuit board (PCB). This way, instead of coordinating with multiple suppliers for PCB fabrication and assembly, all you have to do is hand over your brilliant design ideas, and they take care of the rest.

But hey, it is different from consignment or partial assembly, where you might be responsible for providing components or handling certain stages of production yourself. Here, with turnkey, you get the convenience of one vendor who handles the complete PCB manufacturing process, and in return, you get to save time, reduce risks, and have improved quality control.

In this article, we will be breaking down the meaning of “Turnkey” in PCB assembly, key benefits of turnkey PCB assembly, a step-by-step process overview, and even some tips on how to choose a PCB manufacturer who can deliver high-quality results.

Table of Contents

ToggleWhat Does “Turnkey” Mean in PCB Assembly?

Single accountability: from BOM to shipment

Supplier handles sourcing, component procurement, fabrication, assembly, testing, and logistics.

Basically, the meaning of “Turnkey” in PCB Assembly comes down to single accountability. Let’s say, if you choose our team at Karkhana.io, then we will manage every stage of production, right from your bill of materials (BOM) to the final shipment.

This includes:

- Component sourcing and procurement

- PCB fabrication and assembly

- Electrical and functional testing

- Quality inspections

- Packaging and shipping

So, with turnkey PCB manufacturing, the supplier isn’t just a manufacturer, but they wear multiple hats. They become your project manager, supply chain handler, and quality controller. The approach here makes sure that there is one point of contact, one consistent process, and far fewer communication errors, which, well, is not the case when dealing with multiple vendors.

Benefits of Turnkey PCB Assembly

-

Cost Efficiency

By leveraging established supplier relationships, turnkey providers can often source components at better prices. This way, there will be no need for double-shipping, boards don’t have to be sent from a fabricator to an assembler, and because there is reduced handling, it will also lower the risk and shipping costs.

-

Risk Reduction

When you have a manufacturer who is involved in the early stages of design and procurement, guess what you get? They can spot the potential issues before they even occur. It is because BOM alignment makes sure that the correct parts are sourced, which will reduce the risk of production.

-

Simplified Management

One vendor means one contact point. So, yes, you will not be chasing multiple suppliers for updates or coordinating logistics between them. After all, you want to be able to spend your time and energy on your ideas and design.

-

Time Savings

When all steps are handled under one roof, the hand-off between stages is much faster! Also, with this, you can save so much as it will lead to shorter lead times. This can be a huge advantage in today’s fast-paced product cycles, which will keep you ahead of your competitors.

-

Scalability & Flexibility

Whether you are someone launching your first batch or scaling multiple SKUs, the turnkey PCB manufacturing process adapts to the changing production volumes, that too, without compromising the quality.

Step-by-Step Process Explained

Below, we have added the whole process, so you can understand it better:

Step 1: Design review / DFM Analysis

Before the fabrication begins, there is a design for manufacturability (DFM) check that will ensure that the PCB can be built reliably and also save you some money.

Step 2: BOM finalization & component sourcing

Then the provider will secure all the components from their trusted supplier, which will ensure availability, authenticity, and compliance.

Step 3: PCB fabrication (IPC compliance, materials)

Now comes the fabrication bit, where ideally, high-quality PCB fabrication and assembly will follow \ IPC standards. This includes using the right materials and finishing.

Step 4: Assembly: SMT, THT, mixed technology

And after that, based on your design and what it demands, SMT (surface-mount technology), THT (through-hole technology), or mixed assembly methods are used!

Step 5: Quality assurance: AOI, ICT, X-ray, functional/burn-in testing

Once the product is ready, it has to go through a solid turnkey PCB manufacturing quality control. This can be done with multiple methods, such as automated optical inspection (AOI), in-circuit testing (ICT), X-ray inspection for BGAs, and functional or burn-in testing.

Step 6: Final inspection, packaging, shipping

And finally, the boards that passed the quality check are packed securely and shipped directly to your location.

Quality Controls That Matter:

When it comes to turnkey production, one thing is pretty clear: Quality is a non-negotiable. And well, it isn’t something that happens at the end of the line. No! One has to keep an eye on the whole process. Believe us, if your provider does not treat quality as a priority, then you are choosing the wrong hands to do your work. You will not only deal with delays but also product failures, costly reworks, and everything you don’t want!

And yes, there are standards to these. To name them, ISO 9001, IPC, and RoHS are like a universal language of electronics manufacturing. What are they? Let us break them down:

- ISO 9001 is all about having a solid, repeatable quality management system.

- IPC standards cover the nitty-gritty of PCB fabrication and assembly. This includes solder joint quality, board cleanliness, and acceptable tolerances.

- RoHS compliance ensures the boards are free from certain hazardous substances. This way, the product will be safe for your users and gentle to the environment.

In a world of global sourcing, knowing exactly where your components came from is very important. And when you choose a good turnkey provider, they will be able to trace each part back to its source, complete with documentation and certifications. Basically, solid PCB manufacturing quality control is what brings utmost transparency to the table!

When to Choose Turnkey vs Partial Turnkey

Now deciding what to choose when can be a bit challenging. So here is how you can choose either Turnkey or Partial Turnkey based on where you at, and what you need!

For example, on one hand, turnkey makes the most sense:

- If you are a startup without any internal sourcing or assembly capabilities.

- You need to focus on design and marketing rather than putting time into managing production.

- Your priority is speed, and you want something reliable.

While on the other hand, partial turnkey can be useful if:

- You already have certain components in stock.

- You want tighter control over specific costs.

But hey, there can also be hybrid models where you can supply certain key components while your provider will handle the rest!

How to Choose the Right Turnkey PCB Assembly Partner

If you are wondering how to choose a turnkey PCB assembly manufacturer, this is where you focus on:

- Industry certifications (ISO, IPC, RoHS).

- Proven production capacity to meet your volumes.

- Transparent communication and responsive customer service.

- Engineering support for DFM and testing.

- Strong PCB manufacturing quality control processes.

Another tip? Well, you can ask for past projects, customer references, and their standard lead times. Once you understand what a turnkey PCB assembly manufacturer is and the scope of their services, you will be able to compare options effectively.

Looking for a PCB partner you can rely on? Meet Karkhana.io’s expert team—our turnkey PCB assembly services tick every box. Get in touch with us today.

Conclusion

To recap, what is turnkey PCB assembly? It is a full-service production approach that takes your PCB from design to delivery with one reliable partner handling everything. This way, you can get the benefits of turnkey PCB assembly, like saving on costs, reducing the risks, faster delivery, and better quality control. At Karkhana.io, our goal is to shorten your timelines, maintain consistent quality, and scale production smoothly!