Quality of parts has always been a paramount aspect for electronic manufacturers that helps them in staying ahead of the curve. It not only helps in building trust and loyalty among customers but also leads to cost reduction if you address the quality issues early in the production process. It also gives credibility in the marketplace, upholding your brand’s reputation through electronic manufacturing quality standards.

Karkhana.io has always been at the forefront, keeping in check with the updated iso standards for electronics manufacturing, coordinating with suppliers to produce high quality parts whilst keeping the customer requirements in check.

Table of Contents

ToggleWhat are the quality control methods for an EMS provider?

Component Management

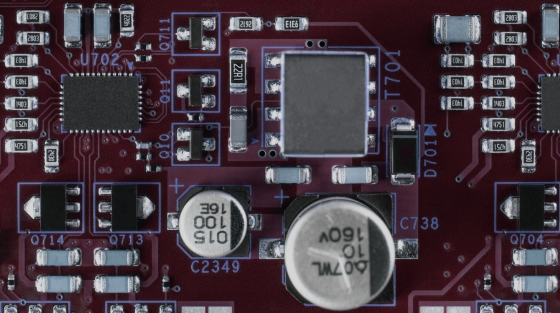

We all are aware that electronic products broadly rely on circuit boards, which are made up of tiny intricate parts. Sourcing and component availability are vital factors to consider for this. Challenges that include component shortages, delayed timelines as well as risk of supply chain disruptions, can be prevented, but only if you adhere to the best practices and follow electronic components quality standard procedures.

Component management practices encompass:

- Source parts from vetted and certified suppliers

- Verify components during design stage

- Follow supply chain management strategies

Process Management

There are certain quality control in electronics manufacturing processes that ensure the products are fit and comply with the regulatory standards set up by the authorities. Process management includes a set of procedures to be followed by manufacturers during different stages.

A few general guidelines and specifications during the designing, assembling and manufacturing stages:

- ISO 9001: General quality management for electronics manufacturers rules.

- IPC-6011: These guidelines outline basic requirements for printed circuit boards.

- J-STD-001: It is utilised to offer detailed guidelines for soldered connections in electronics and electrical assemblies.

- IPC 610-A: This is the most commonly employed inspection standard for electronic items, aiming to standardise the assembly process

Data Management

Data management is an essential aspect for faultless products. Poor data management practices can lead to reduced efficiency and productivity as well as lost opportunities due to lack of agility.

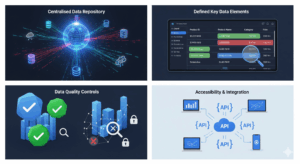

Effective data management strategies include the following:

- Create a centralised data repository, ensuring consistency across the company.

- Define key data elements and attributes, including product descriptions, specifications, and pricing.

- Implement data quality controls to maintain accuracy and completeness.

- Ensure accessibility to product data through APIs and integration with other systems for widespread usability.

How does Karkana.io take care of the quality aspects as an EMS provider?

Sourcing of Quality Components

Potential issues can arise based on the type of intricate components chosen for each board and their proper attachment. Karkhana.io holds a supplier base that specialises in electronic components production. We make sure the supply of reliable high-quality parts is not interrupted with our vast supplier base, offering scalable manufacturing solutions aligned with electronic manufacturing quality standards.

Regular Testing and Inspection

Testing and inspection is not conducted only at the final stage of the product. It has to be taken care of at different stages, i.e. assembly, manufacturing and when the final product is made. Even the components that are to be used at early stages go through thorough examination based on electronic components quality standard benchmarks.

Karkhana.io detects and rectifies defects with regular testing, ensuring that products meet the required quality standards before reaching customers

Supplier Management

Karkhana.io has carefully selected suppliers that provide high-quality materials and components. We have also maintained open communication channels such as the supplier and procurement portal, to address any issues promptly and in a simplified manner. We have fostered strong relationships with suppliers, making sure that the iso standards for electronics manufacturing are kept in check, throughout the supply chain.

Compliance to Regulatory Standards

Karkhana.io ensures compliance with relevant industry standards and regulations. We take care of product quality, safety and market acceptance to maintain customer trust as well as safety from potential risks by adhering to electronic manufacturing quality standards.

Why is Karkhana.io your go-to EMS provider?

Karkhana.io is your one-stop solution to cater to all your electronic manufacturing requirements. With a network of 500 vetted and certified suppliers nationwide, well-versed in the intricacies of electronics integration and are trusted by top-tier pcb manufacturing companies in india, assuring you of optimal results!

Why do we stand out?

- Turnkey and contract manufacturing solutions

- Dedicated assembly lines for high-volume PCB assembly

- Global Sourcing of raw materials

- Integrated quality management for electronics manufacturers system

Our flexible pcb manufacturer in india services enable product efficiency and quality across orders of all sizes from small batches to large volumes, while offering box build solutions along with product localisation capabilities.

If you’re looking for an EMS provider that meets the technical capabilities, contact us today. Let us help you reach the optimal outcome for all your manufacturing requirements. To get started, simply email Pushpalaxmi Vanniyar at pushpalaxmi@karkhana.moshimoshi.tech with your specifications or fill out the form below.

Frequently Asked Questions:

Q1. What are the key ISO standards for electronics manufacturing?

Karkhana.io follows updated ISO standards for electronics manufacturing, including ISO 9001 for quality management, ensuring consistent production quality and regulatory compliance.

Q2. How is electronic components quality standard maintained?

By sourcing parts from certified suppliers, verifying components at the design stage, and following strict inspection protocols, Karkhana.io adheres to high electronic components quality standard benchmarks.

Q3. What methods ensure quality control in electronics manufacturing?

Quality control in electronics manufacturing is ensured through process management, regular testing at all production stages, and compliance with regulatory guidelines like IPC-6011 and J-STD-001.

Q4. How does Karkhana.io implement quality management for electronics manufacturers?

Karkhana.io integrates a centralized data system, supplier management, and continuous testing to maintain quality management for electronics manufacturers, guaranteeing reliable and defect-free products.

Q5. Why are electronic manufacturing quality standards important?

Following electronic manufacturing quality standards ensures product safety, customer trust, and market credibility while reducing costs due to early detection of defects.