Welcome to Karkhana.io, your trusted manufacturing solutions provider for the oil & gas industry. In this blog, we will explore what is hot tapping and cold tapping, two commonly used methods in pipeline maintenance and modification. Understanding their distinctions and benefits will help you make informed decisions for your operations.

Hot Tapping: Keeping the Flow

Hot tapping, also known as pressure tapping or live tapping, is a method used to create a connection or branch in an active pipeline without interrupting the flow of the product. This technique involves drilling or cutting into the pipe while it is under pressure, allowing for the installation of valves, fittings, or additional lines.

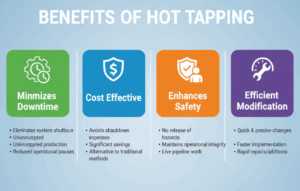

Benefits of Hot Tapping

-

Minimizes downtime: Hot tapping eliminates the need for shutting down the entire system, enabling uninterrupted production and reducing downtime.

-

Cost-effective: By avoiding system shutdowns and the associated expenses, hot tapping offers significant cost savings compared to traditional pipe modification methods.

-

Enhances safety: With the ability to work on live pipelines, hot tapping reduces the risk of releasing hazardous substances and maintains operational safety.

-

Efficient modification: Hot tapping allows for quick and precise modifications, enabling faster implementation of changes or repairs.

Cold Cutting: Precision in Pipe Modification

Cold cutting, as the name suggests, involves cutting or severing pipelines without the use of heat. This technique is commonly used when modifications are required, such as removing a section of the pipeline or preparing it for repairs.

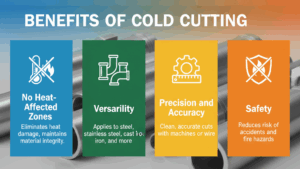

Benefits of Cold Cutting

-

No heat-affected zones: Cold cutting eliminates the risk of heat damage to the surrounding area, ensuring the integrity of the pipeline material.

-

Versatility: Cold cutting techniques can be applied to a wide range of pipe materials, including steel, stainless steel, cast iron, and more.

-

Precision and accuracy: Cold tapping machine and other cold cutting methods, such as mechanical sawing or diamond wire cutting, offer high precision, resulting in clean and accurate cuts.

-

Safety: Cold cutting techniques are generally safer compared to methods involving heat or flame, reducing the risk of accidents or fire hazards.

Choosing the Best Method

The choice between cold tapping vs hot tapping depends on various factors, including the specific requirements of your project, pipeline conditions, and safety considerations.

Hot tapping is ideal when you need to make connections or add branches to an active pipeline without interrupting the flow. It offers minimal downtime, cost savings, and efficient modifications. On the other hand, cold cutting pipe procedure is preferred for precise cuts, repairs, or removal of pipeline sections, especially when heat-affected zones are a concern.

Discover Karkhana.io’s Expertise in Oil & Gas Industry

At Karkhana.io, we provide cold tapping services and understand the unique needs of the oil & gas industry. Our manufacturing capabilities and expertise allow us to provide flexible and scalable solutions for your manufacturing requirements.

We adhere to stringent industry standards, employing the latest technologies and best practices to ensure that our solutions meet the highest level of integrity and reliability.

Frequently Asked Questions

1. What is hot tapping and cold tapping?

Hot tapping is creating a connection on a live pipeline without stopping the flow, whereas cold tapping involves cutting or modifying a pipeline without heat. Both methods are used for pipeline maintenance and modifications.

2. How does cold tapping differ from hot tapping?

Cold tapping vs hot tapping mainly differs in the operational conditions. Hot tapping works on active pipelines under pressure, while cold tapping is done when the pipeline is depressurized or requires precise cuts without heat.

3. What equipment is used for cold tapping?

A cold tapping machine is used to perform cold tapping procedures efficiently, ensuring precision and safety without affecting the pipeline’s structural integrity.

4. What is the cold cutting pipe procedure?

The cold cutting pipe procedure involves mechanically cutting or sawing a section of the pipeline without heat, often using a cold tapping machine or diamond wire cutting, to ensure accurate and safe modifications.

5. Can Karkhana.io provide cold tapping services?

Yes, Karkhana.io offers professional cold tapping services for various pipeline modifications, ensuring safety, precision, and minimal operational disruption.