Electronics Manufacturing Services

1L Sq ft Mfg

Shop Floor

1.5 Mill Components/Hour

7 SMT

Lines

5 Through

Hole Lines

Class 100K

Clean Room

100%

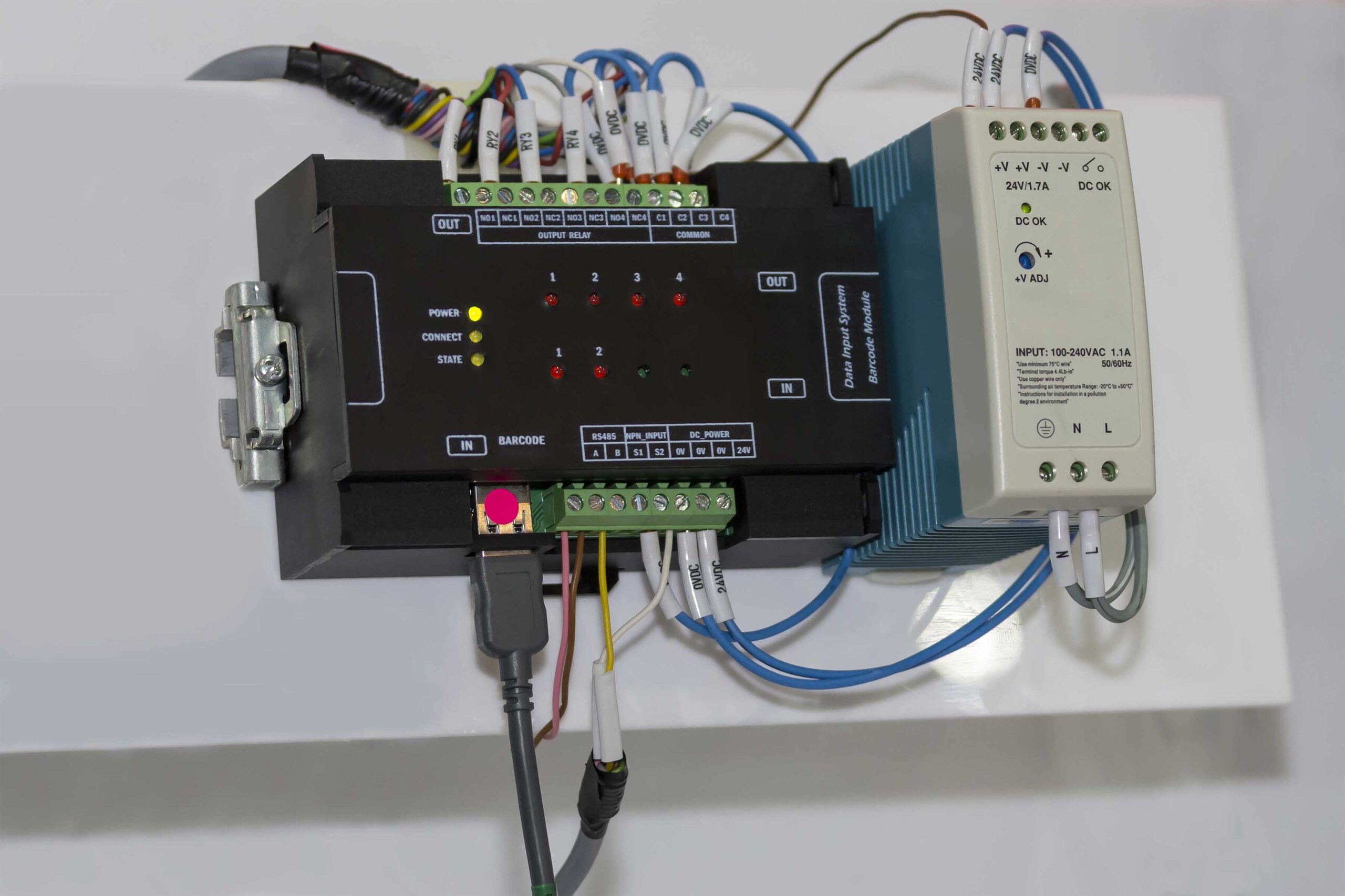

Traceability

Our Capabilities

Component Sourcing & BOM Management

Component Sourcing & BOM Management

Procurement of high-quality components with supply chain optimization.

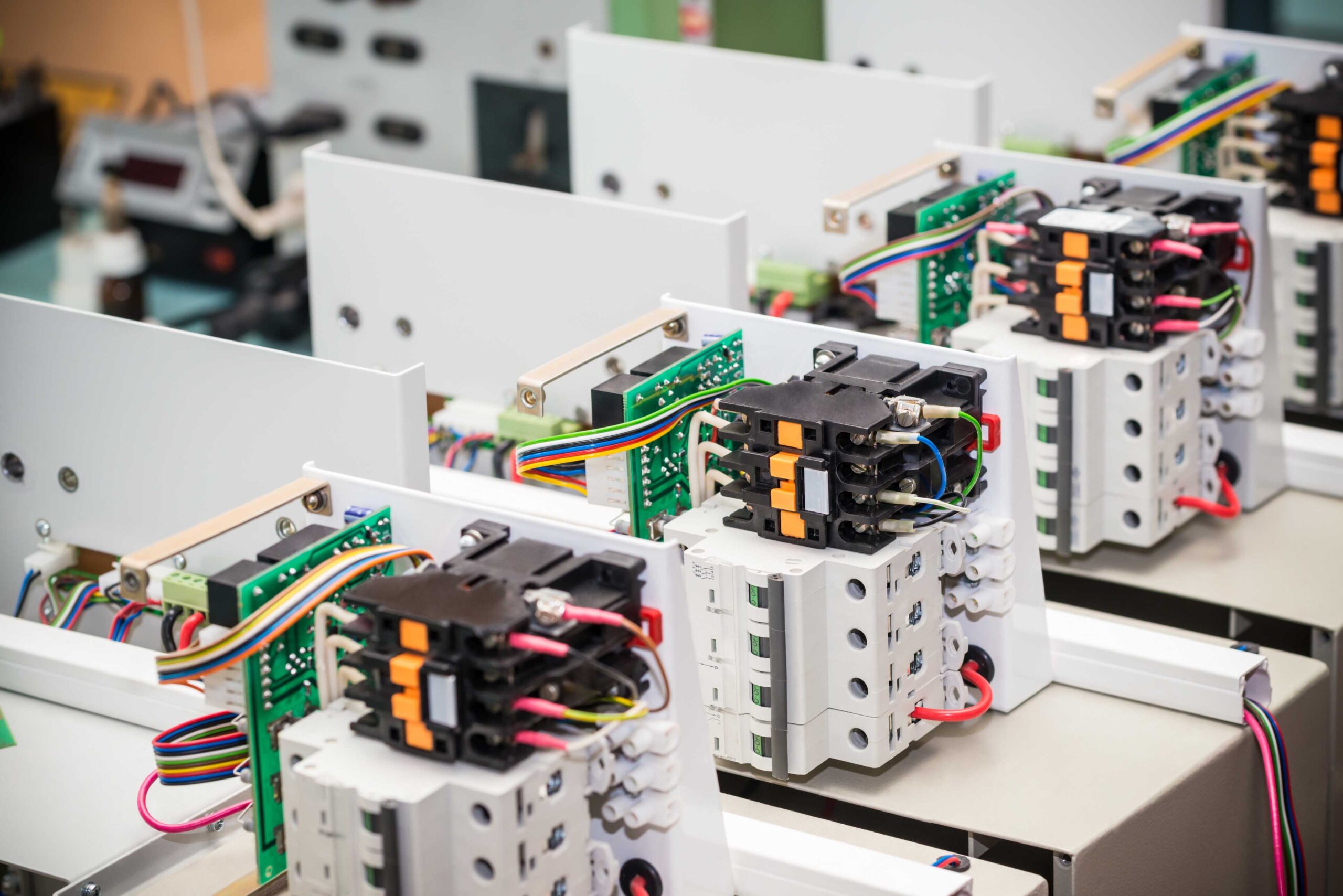

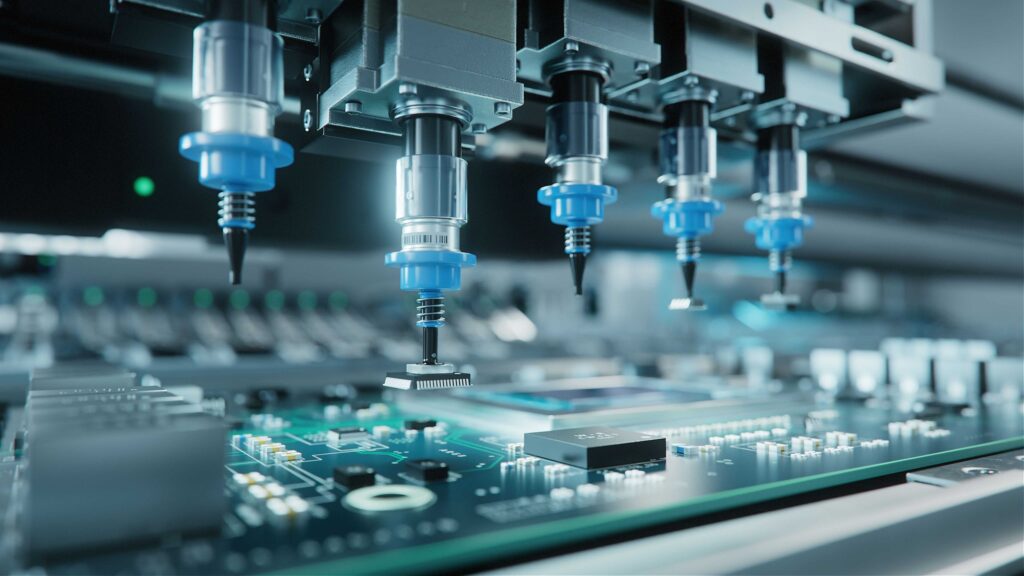

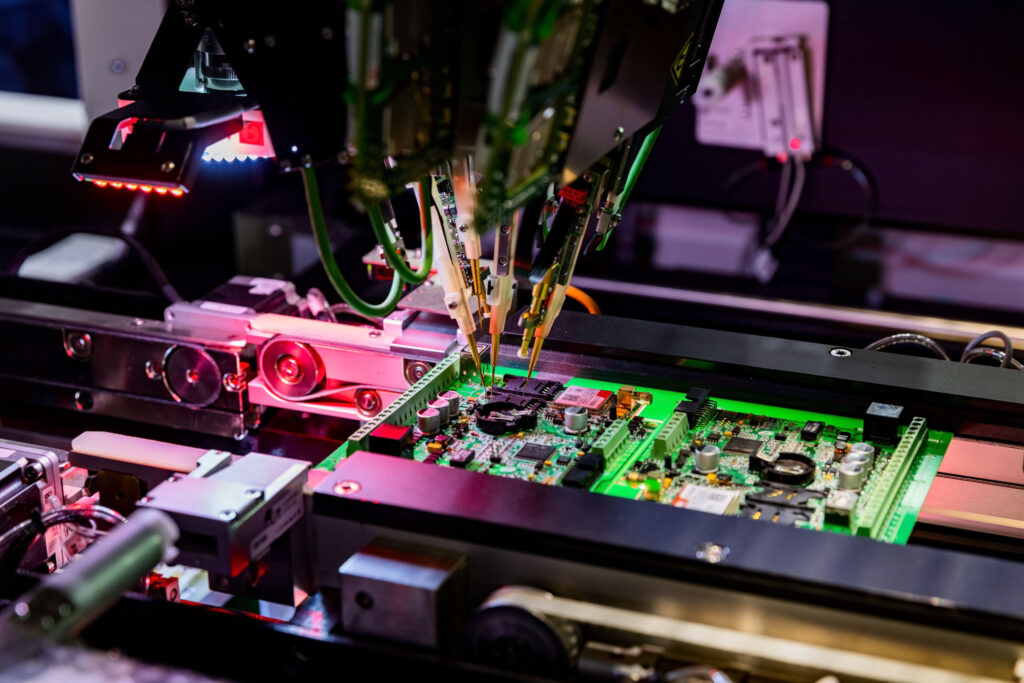

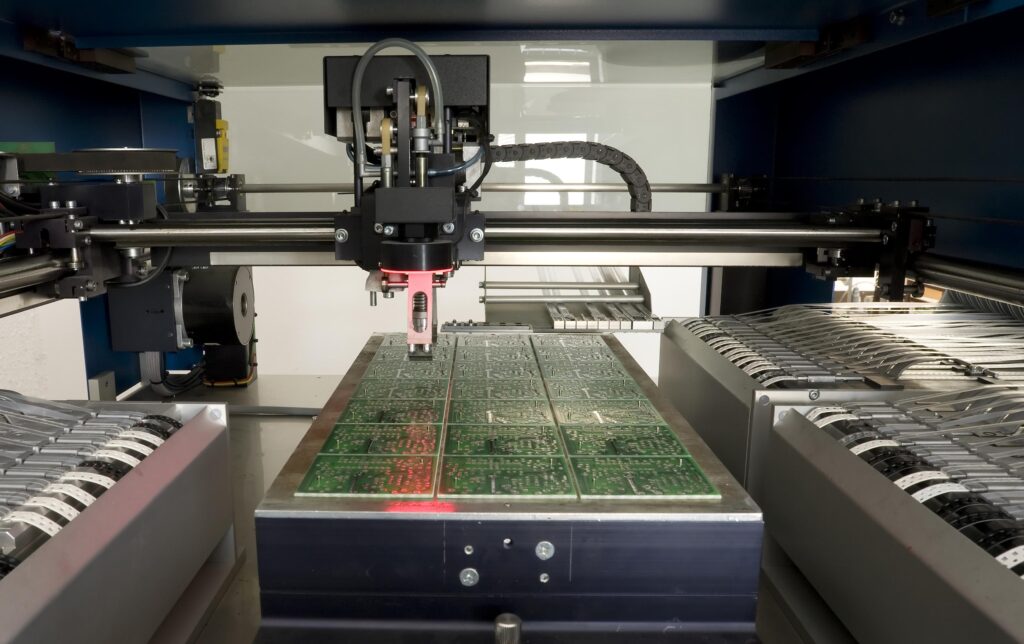

SMT Lines Assembly

SMT Lines Assembly

With 7 high-speed automated pick-and-place machines, we handle up to 1.5 million components per hour. Our top-tier equipment from Yamaha, Panasonic, Fuji, and Heller ensures unmatched precision and efficiency.

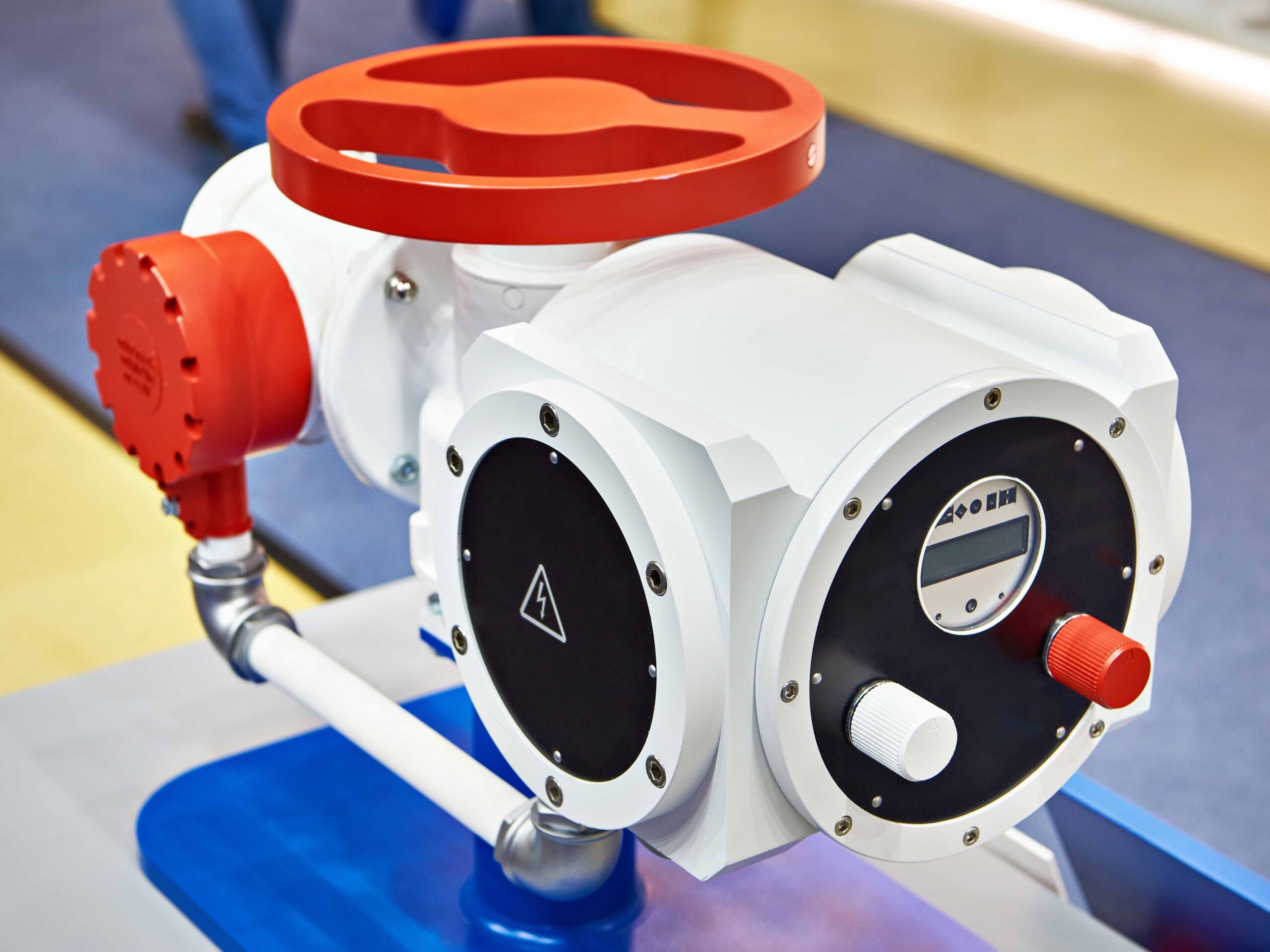

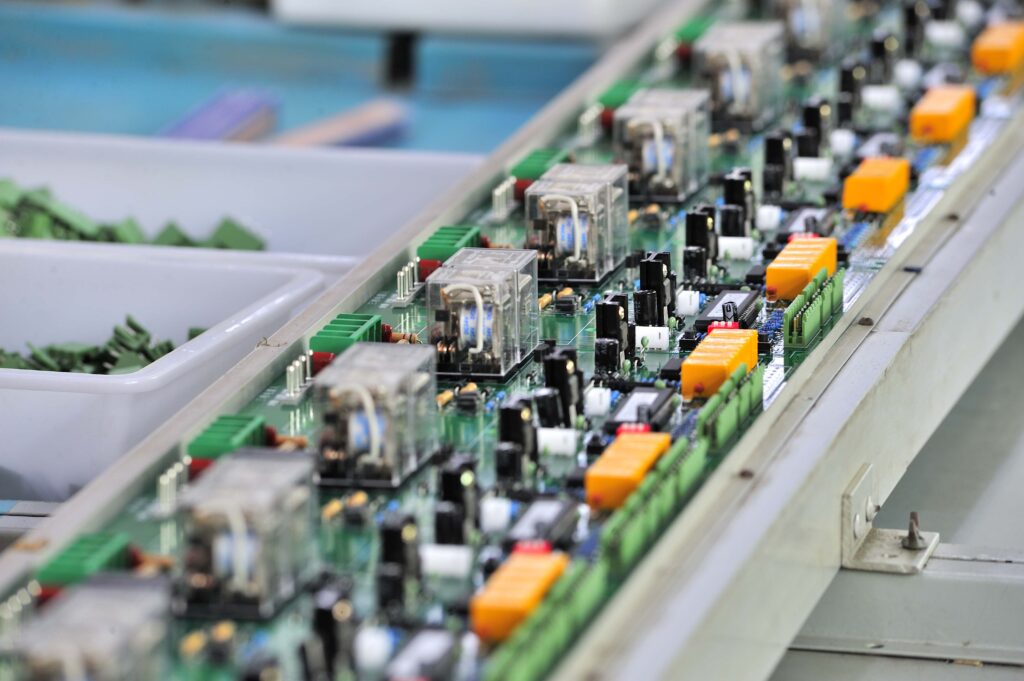

Wave and Robotic Soldering

Wave and Robotic Soldering

With two dedicated robotic lines featuring dynamic temperature control and capabilities for both point and drag soldering and our advanced wave soldering machine perfect for through-hole technology, large components, and glue-side SMD applications, we deliver reliable and consistent soldering every time.

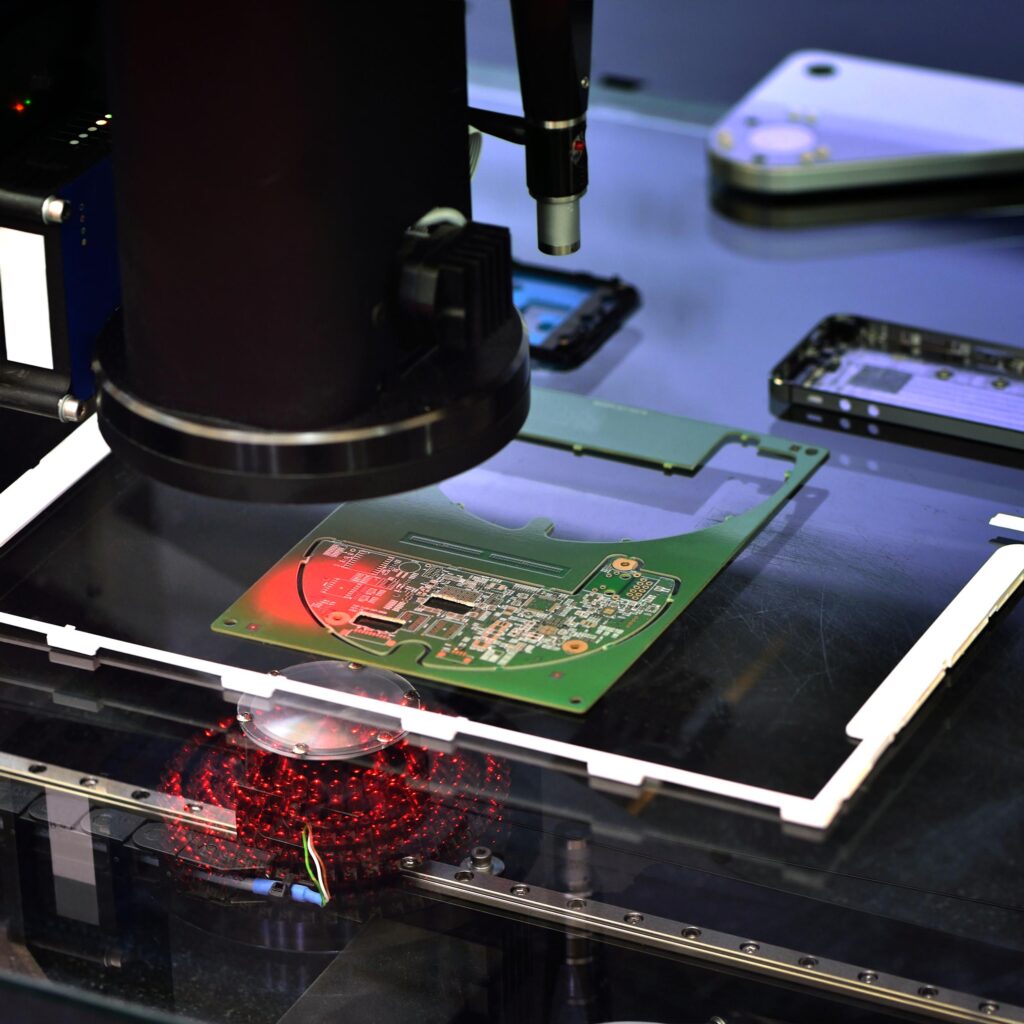

X-Ray and AOI (3D) Inspection

X-Ray and AOI (3D) Inspection

Non-destructive testing checks hidden solder joints, BGA, and fine-pitch components. It also performs solder fillet checks for through-hole and ground pad joints, detecting defects in components and soldering with incredible precision ensuring top-notch quality.

Conformal Coating

Conformal Coating

Using acrylic and resin-based coatings, applied through spray or brush techniques, we provide dependable protection against environmental elements.

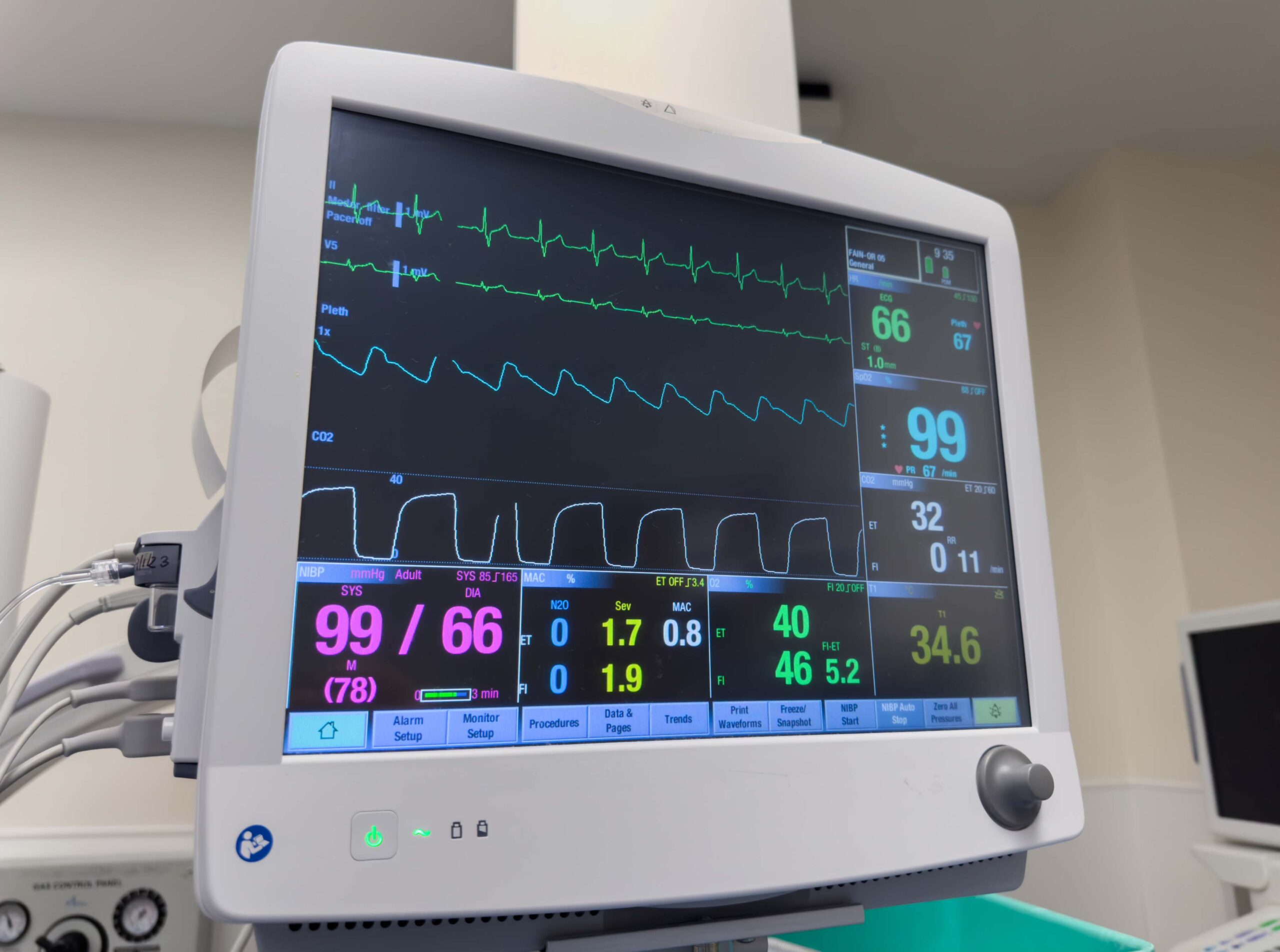

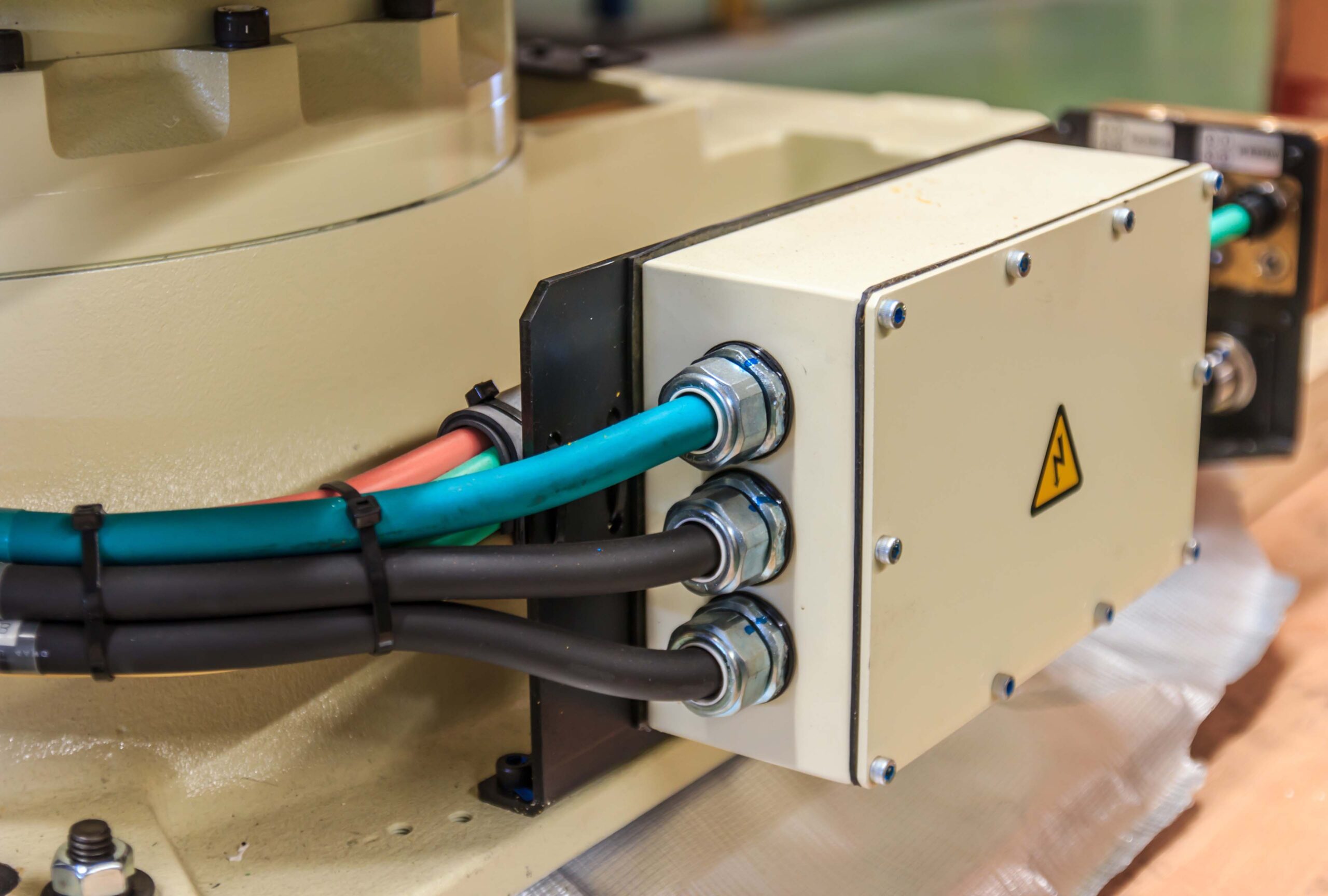

Testing & Validation

Testing & Validation

From In-Circuit Testing (ICT) and Functional Testing (FT) to Environmental Testing, our thorough processes guarantee every product meets top performance and reliability standards.

Statistical Process Control (SPC)

Statistical Process Control (SPC)

Real-time monitoring keeps production on track, ensuring quality and enabling quick adjustments to maintain high standards.

Inventory, Warehousing & Logistics Management

Inventory, Warehousing & Logistics Management

Our In house ERP portal provides end-to-end visibility on inventory management.

Our Offering

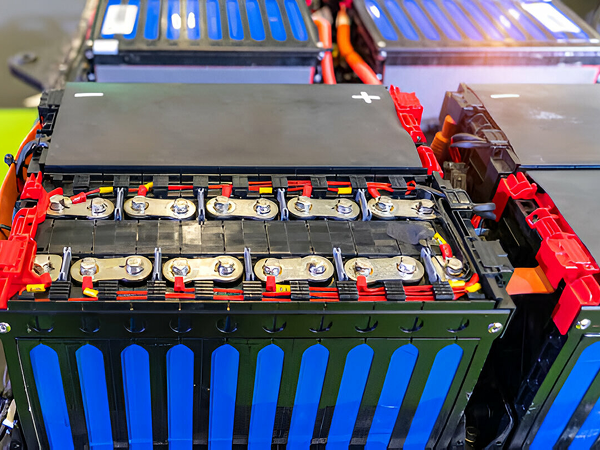

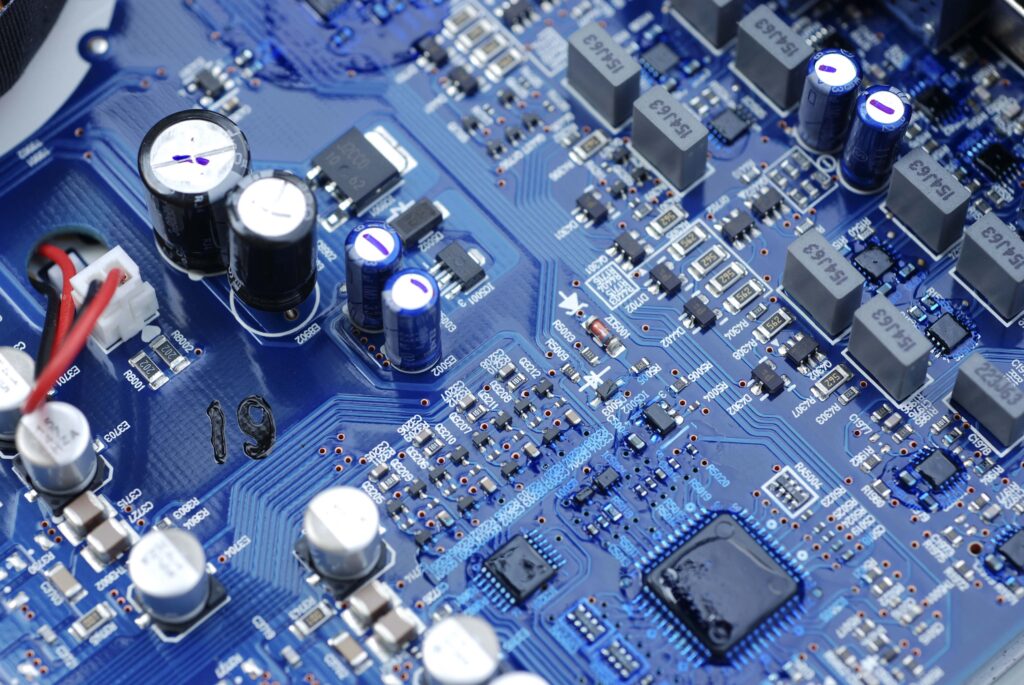

Surface Mount Technology (SMT) PCBA

Fully automated, high-speed assembly for modern, compact designs supporting fine-pitch components, BGAs, QFNs, and microcontrollers.

Through-Hole/Mixed Technology (THT) PCBA

Combination of SMT and THT for complex hybrid assemblies with Reliable assembly for high-power and high-mechanical strength applications.

High-Density Interconnect (HDI) PCBA

Advanced multi-layer PCBs with fine-pitch components. Suitable for smart devices, IoT, and high-speed applications.

Rigid, Flex &

Rigid-Flex PCBA

Standard FR4-based PCBs, Thin, bendable circuits and Hybrid solutions for compact and high-reliability applications.

Certifications

Industry Certifications

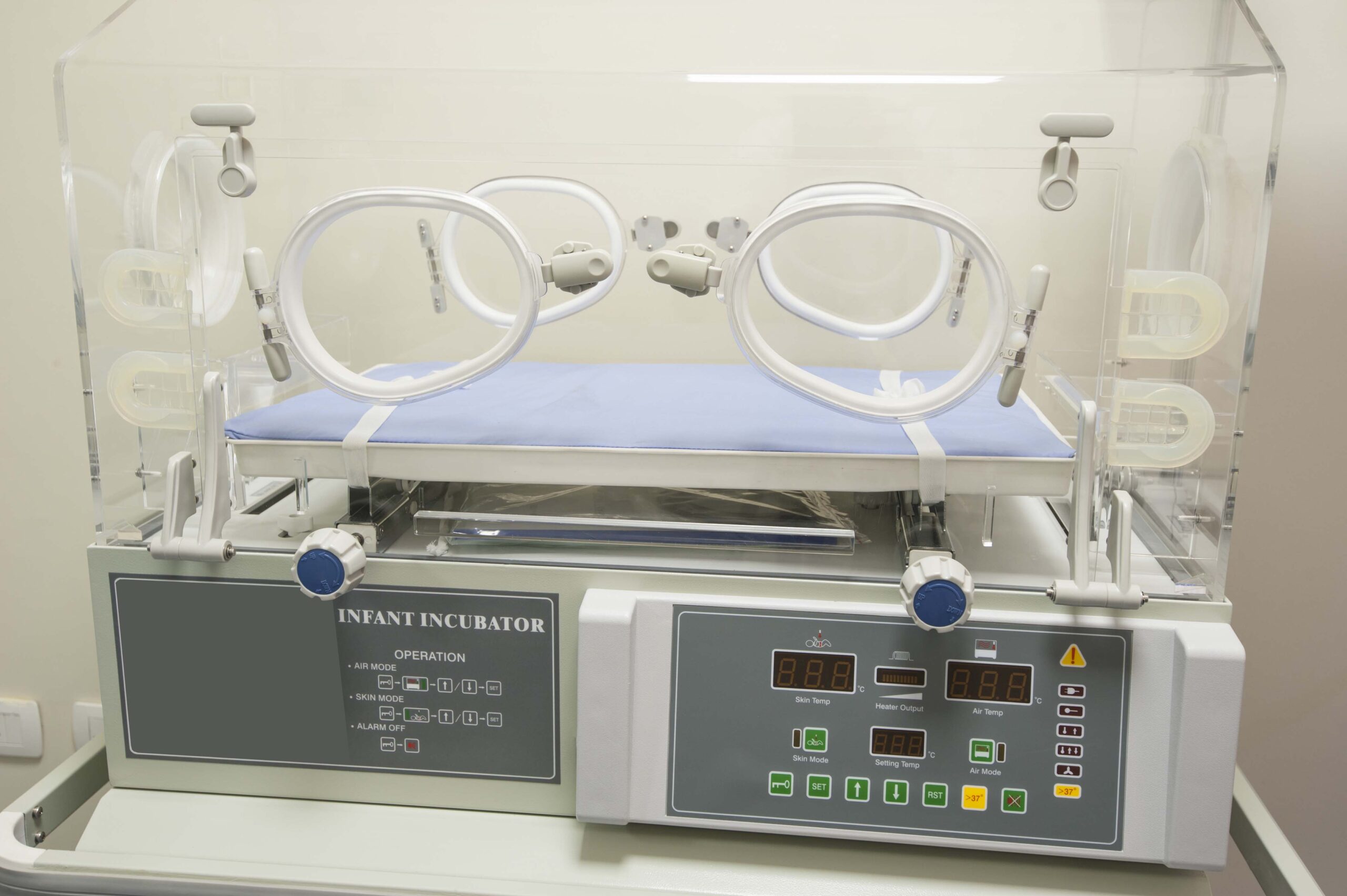

Industries Served

Industries Served

Your Trusted Partner for Precision Manufacturing – Contact Us Today!

Frequently Asked Questions

How early in the product development cycle should we engage with Karkhana.io for EMS support?

You should link up with Karkhana.io after your product design is solid and you are preparing to make pilot or production. The earlier we are brought on board and especially in the design-for-manufacturing (DFM) stage, the better able we would be to work on making your product more scalable, sourced, and cost-effective. As an experienced Electronic Manufacturing Services Company, we do not pretend to be a prototyping shop, but we deliver the most when there is a straightforward way to production. In case you will launch or scale in the near future, you should collaborate early and achieve a faster turnaround time and smaller gaps between design and manufacturing.

Can you support mixed-technology boards with both SMT and THT components?

That is right, Karkhana.io, as a leading Electronic Manufacturing Services Company, focuses on the assembly of mixed-technology PCBs, i.e. with both SMT and THT components. There are 7 high-speed SMT lines with 5 through-hole specific lines inclusive of wave and robotic soldering. Such configuration enables us to deal with intricate hybrid assemblies.

We’re concerned about IP and firmware safety. How do you address that?

Design files, BOMs and firmware, CAD and other customer data is all handled under NDAs and restricted access. Programming and upload of Firmware are accomplished in a secured fashion with program and interface files that are tracked and with restricted access to personnel. Our customer IP is not shared or reused. As a trusted Electronic Manufacturing Services Company, we put your sensitive data under protection through the process isolation of the manufacturing lifecycle.

What makes Karkhana.io different from other EMS providers?

The uniqueness of Karkhana.io lies in the fact that we are able to integrate flexibility and the speed of release in the same location. As opposed to the traditional EMS providers, we provide real turnkey solutions. Electronics, mechanicals, sourcing, assembly, testing and logistics are some of our services. We target the high-growth businesses that require rapid scaling, but do not have to build their own operations. Our dynamic systems deal with a number of SKUs, different volumes, and short iterations with ease. Through great supply chain awareness, process regulation, and working with others, we offer manufacturing with reduced friction. As a modern Electronic Manufacturing Services Company, Karkhana.io ensures speed, scalability, and end-to-end reliability for growing businesses.

Can you support PCBs with fine-pitch components or BGA packages?

Yes, Karkhana.io will accommodate PCBs with fine-pitch features and BGA (Ball Grid Array) packages. The smallest components that our SMT lines are capable of mounting have pitches as low as 0.25 mm and a size of 03015. We offer 3D AOI inspection and X-ray inspection, as well as high-quality pick-and-place machines, which play a critical role in aspects of alignment, reliable soldering, and the ability to detect hidden defects—a requirement in fine pitch and BGA assembly. Going from small and dense to multilayered designs, we offer quality and repeatability on a production scale.

Our PCBA uses a mix of local and imported components. Can you manage hybrid sourcing models?

Hybrid sourcing is something we manage regularly, many of the products we build use a mix of locally available parts and imported components. Our team works closely with your BOM and vendor preferences to ensure smooth coordination across both supply chains. We’re used to handling staggered lead times, import documentation, and buffer planning where needed. As an experienced electronics manufacturing services company in India, we make sure component availability never becomes a bottleneck, whether the parts are coming from India or overseas.

Do you provide design services?

Design is not an individual service that we offer. Nonetheless, once you are ready to create production, our engineering team is there to assist you in DFM (Design for Manufacturability) and DFA (Design for Assembly) reviews. We assist in the identification of possible risks and cost drivers or assembly-related issues earlier. This enables you to make your design enhanceable in scale, reliability, and flawless implementation. It therefore means that you experience accelerated cycles of production, reduced revisions, and enhanced product build with no additions to your in-company design staff. As an experienced Electronic Manufacturing Services Company, Karkhana.io ensures that your transition from design to production is smooth and scalable.

Do you manufacture Bare PCBs?

We don’t make bare PCBs in-house. Instead, we rely on a trusted network of PCB fabrication partners, both in the U.S. and abroad, to source high-quality bare boards as part of our complete offering. This enables us to oversee the entire process from PCB fabrication to assembly, testing, and final integration. We ensure quality, traceability, and faster turnaround without making you deal with several vendors.