Let’s be honest for a second: when you’re building a new product, the pressure to keep costs low starts haunting you from Day 1. Investors want lean operations. Teams want fast execution. Founders want to show that the “unit economics look good.” And somewhere in that chaos, cost becomes this giant cloud hanging over everyone’s head. That is usually the moment someone says, “Hey, maybe we should optimize costs early?”

That is usually the moment you hear someone say, “Hey, maybe we should optimize costs early?” And well, no matter how sensible that sounds, because of course everyone wants to save money. But here is a twist: early cost optimization often does the exact opposite of what it promises. Instead of making your product cheaper, it silently builds up future expenses, delays, rework, poor yield, and sometimes complete redesigns.

That is why understanding what cost optimization is, how cost reduction strategies actually work, and especially how they apply inside real-world manufacturing is so important. Because when done wrong, cost optimization creates problems that keep showing up again and again, from prototyping to mass manufacturing.

Through this article, we will break things down and understand why early cost-cutting backfires, the most common cost optimization mistakes, and how companies like Karkhana.io help teams build products smarter and not just cheaper.

Table of Contents

ToggleWhy Early Cost Optimization Backfires?

The answer is pretty simple! Early cost optimization backfires mostly because product development moves in layers. You learn something new at every stage: design, DFM, prototyping, testing, EVT, DVT, PVT, and each stage reveals a new truth about your product.

When you jump into product cost management too early, you are basically making decisions with incomplete information. And this incomplete information will always lead to bad choices. Here is the biggest reason why it all goes so wrong:

- You do not know your real cost drivers yet. Like, what the product does, what components it needs, what the performance expectations are, how complex the assembly will be, what tolerances are realistic, etc. So, trying to do cost management in manufacturing at this point is like trying to decide the price of the house before you even see the land.

- You start making decisions based on the price, instead of the performance. No matter how alluring the price is, if it cannot function as it should, what is the point? For example, a cheap connector looks like a big win at first. But what if that connector increases the failure rate by 3%? Or requires manual soldering instead of automated assembly? Or has inconsistent availability?

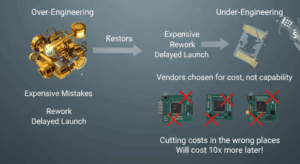

- Early cost optimization pushes the teams into extremes. So it either leads to over-engineering or under-engineering. Both are expensive mistakes, both increase rework, and well, both also delay the launch.

- Oftentimes, vendors get chosen for cost, not for their capability. But later is when you find that they cannot handle tight tolerances, their process is not stable, they cannot scale beyond 50 units per day, and their testing is not mature.

- You end up cutting costs in the wrong places. This is one of the most dangerous cost reduction strategies, where the target is on the wrong things. They will reduce PCB layer count too early, eliminate the need for mechanical support, ski testing to save time, use cheaper passives with poor tolerance, etc., and let us tell you, these decisions will actually cost you 10x more later on!

Common Cost Optimization Mistakes in Early Product Development

To make this super clear, let’s talk about the most familiar and the most painful cost optimization mistakes that teams make. Each mistake is pretty common, so make sure you have a good understanding of what is cost optimization to save yourself from these:

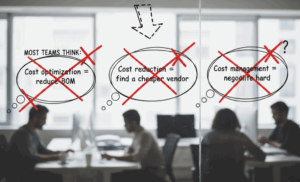

Most teams think:

- Cost optimization = reduce BOM

- Cost reduction = find a cheaper vendor

- Cost management = negotiate hard

But real cost management in manufacturing is actually deeper. It’s about reducing inefficiencies across:

- Design

- Sourcing

- Assembly

- Quality

- Supply chain

- Lead times

- Rework cycles

Cutting costs is easy, but optimization is intelligent.

- Skipping DFM is like building a house without checking whether the soil can hold it. If you ignore the DFM, then vias get too close, components are hand-soldered unnecessarily, stencil apertures are wrong, pick-and-place struggles, and assembly requires manual rework.

- Not understanding the real cost drivers is also pretty common. If you ask us, true product cost management asks questions like: which parts affect the yield? What causes the most rework? Which processes have the highest setup cost? Which materials create consistency issues? This analysis can literally change the whole game!

- Early cost reduction decisions often target the wrong areas, like reducing PCB layers, using alternative components without ever testing, skipping EMI/ESD checks, etc. These shortcuts are what then lead to RMA spikes, field failure, safety issues, poor thermal performance, etc.

- Last but not least, these early “cheap” prototypes rarely ever scale. If your component or vendor selection doesn’t scale, then lead times will explode, costs will rise, quality will drop, and basically, the whole process will become very unpredictable for you!

Also Read : The Importance of IPC ( inter process Communication ) Standards in PCB Assembly

How to Avoid These Pitfalls?

Want to know some good news? Well, avoiding these problems is simple when you approach costs the right way. This is where real product cost management begins, not with cutting, but with smart planning.

- Delay cost optimization to the right stage

- Use design for manufacturability early and often

- Involve your manufacturing partner, like Karkhana.io, early in the process

- Use cost reduction strategies the smart way

- Work with integrated, not fragmented partners

Final Thoughts

As we reach the end of this article, one thing we can tell you is that early cost optimization seems tempting. Everyone wants to save money, look efficient, and have good unit economics. But most people forget that true efficiency doesn’t come from cutting early; it actually comes from understanding the product deeply first/ Cost reduction is a short-term cut, but cost optimization is what a long-term strategy is. And well, we can tell you from our experience at Karkhana.io that a long-term strategy will always win.

If you avoid the common cost optimization mistakes, involve your manufacturing partner early, and approach cost management in manufacturing as a structured, thoughtful process.

FAQ’s

1. What are the four pillars of cost optimization?

The four pillars are cost visibility, process efficiency, technology optimization, and strategic sourcing. Together, they help organizations identify waste, streamline operations, and make smarter spending decisions.

2. What are the challenges of cost reduction and cost control?

The main challenges include limited visibility into spending, resistance to process change, impact on productivity, and difficulty maintaining long-term savings without continuous monitoring.

3. What is the difference between cost optimization and cost reduction?

Cost reduction focuses on cutting expenses quickly, often in specific areas. Cost optimization is a broader, ongoing strategy that balances cost savings with performance, ensuring the business grows efficiently instead of just spending less.

4. How does data analytics help with cost optimization?

Data analytics provides real-time insights, uncovers spending patterns, identifies inefficiencies, and supports data-driven decisions, making it easier to optimize costs without hurting operations.