There is no doubt that the electronics manufacturing process might look seamless from the outside. All you have to do is press a button, and your favourite gadget comes alive. But behind that sleek finish lies a web of intricate steps, hundreds of components, and a constant dance between precision and timing.

From sourcing components to final testing, every stage in the electronics manufacturing process demands quite a lot of attention to detail. And yet, even the most experienced manufacturers face hurdles. Delays, defects, supply issues. You name it, it happens!

At Karkhana.io, we have seen these challenges first hand. Working closely with startups and engineers, we actually help to transform an idea into a real, market-ready product. So if you have ever wondered why production timelines stretch or what really happens inside an electronics factory, let’s break it down!

Table of Contents

ToggleWhat Is The Manufacturing Process Of Electronics?

Let’s start with the basics. The electronics manufacturing process is essentially how electronic devices are made. Taking it from the concept to the final product. It covers design, component sourcing, assembly, testing, and, not to forget, quality control!

But within this broad scope, there is something very important, which is the electronic manufacturing process flow. You can think of this one as the blueprint or roadmap that actually tells every team what happens when. So it includes:

- Design, which is the idea phase. In this very first step, engineers create circuit designs and test their feasibility.

- Now, it’s time to source components. So one has to get the right chips, resistors, and capacitors from the suppliers. And believe us, this is one of the trickiest parts of the electronics manufacturing industry due to fluctuating supply chains.

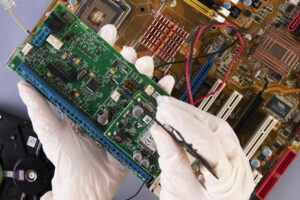

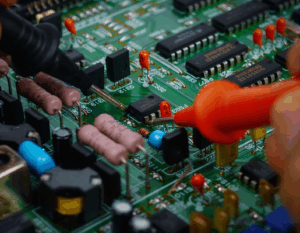

- The heart of the device is the PCB, and the next step is PCB assembly. This is where the printed circuit board assembly process (PCB assembly process) takes place. All the soldering components onto the boards through SMT or TMT are done at this stage.

- At this step, someone ensures that the boards and devices are performing as intended. So quality control and testing are done by a professional.

- Finally, it’s time for assembly and packaging. This is the last stage before the product heads to customers.

Each of these steps is deeply interconnected. A delay in one phase can easily affect the rest of the electronic manufacturing process flow. And well, that’s exactly where most of the challenges begin!

Also Read : When and Why to Move from In House Assembly to Contract Manufacturing

Common Electronics Manufacturing Process Challenges

Guess what? Even with the best technology and planning, things don’t always go as smoothly as the assembly line suggests. Below, let’s look at some of the most common electronics manufacturing process challenges manufacturers face today.

-

Component Shortages & Supply Chain Issues

If there’s one thing that gives everyone in the electronics manufacturing industry sleepless nights, it’s this. We mean, a single missing microchip can bring an entire PCB assembly process to a standstill. And let’s be honest, supply chains today are totally unpredictable. Imagine building a puzzle and realizing you’re missing one piece. That would be frustrating, right? That’s pretty much what this feels like, just on a much larger (and more expensive) scale.

-

Quality Control and Defects

Let’s say all the parts arrive on time. Now, maintaining quality is a whole other challenge that many companies deal with. Especially when you are producing thousands of units, consistency is something you don’t want to mess with. And this can be disrupted due to something as small as slightly off soldering temperature, a misplaced component, or even too much humidity.

-

Design for Manufacturability (DFM) Gaps

Here is another big challenge: Just when the designs seem to look perfect on screen, you see how it turned into a nightmare on the factory floor. This usually happens when there is weak communication between design and manufacturing. These gaps can literally be silent killers and slow everything down. So you get longer production cycles, more costs, and more frustration during the printed circuit board assembly process.

-

Rapid Technological Changes

One thing you should know is that the electronics manufacturing industry moves very fast. New chips, faster processors, and smarter sensors. Blink, and what was cutting-edge six months ago is now outdated. So clearly, if your process is not flexible enough, then you have our best wishes!

-

Cost Pressure and Time-to-Market

And then comes the classic battle, which is the cost vs time. The thing is, everyone wants things faster, cheaper, and better. But in manufacturing, cutting corners usually bites back. Even if you skip one test, you might just lose weeks later fixing what went wrong.

How To Mitigate These Challenges

Now that we’ve talked about what can go wrong, let’s look at what can make it right, and that’s exactly where we step in. And our goal is not just to build things, it’s to make the entire electronic manufacturing process flow simpler, smarter, and stress-free for businesses of all sizes. Here is how that happens:

-

Building a Reliable Supply Chain

Here, we only go with trusted vendors and do not depend on a single supply. So yes, we source verified components early in the electronics manufacturing process, so your company can avoid those last-minute shortages.

-

Collaborative Design Approach

You can have the best design in the world, well, if it’s too hard to build, it’s only half a win. That’s why bridging the gap between design and manufacturing matters so much.

We have the engineers, designers, and production teams who ensure that every decision makes sense on the factory floor. The result? Fewer redesigns, fewer surprises, and a much smoother flow.

-

Quality at Every Step

Most people think of quality checks as a chore that happens at the end. But that’s not true! We know that quality is baked into every stage of production. From checking components to running inspections during the printed circuit board assembly process, the focus stays on preventing problems before they can even appear.

-

Embracing Smart Manufacturing Tools

We all know how fast the electronics manufacturing process is changing. We have smart systems like data tracking, AI-powered inspections, and real-time analytics, which are not just add-ons, but that’s just how we work. This way, we keep the efficiency visible, measurable, and repeatable.

-

Cost Optimization Without Compromising Quality

Every project comes with a budget. So, the real trick here is to get the most out of it without cutting corners. That’s exactly what we help our clients achieve. How do we do it? Well, we simplify workflows, reduce manual errors, and streamline the whole PCB assembly process. And this is how we get faster turnaround times, good quality, and better cost control every time!

-

End-to-End Support

From the sketch to the final round of testing, Karkhana.io stays with you at every step of the electronics manufacturing process. You get one team, one process, and a clear path that will take your idea to reality.

Conclusion

The electronics manufacturing process might be complex, but it doesn’t have to be chaotic. Or at least, THAT chaotic. The key lies in understanding where challenges come from and having the right systems and partners to handle them.

And well, by improving communication, embracing smart tools, and focusing on quality from the start, companies can simplify their electronic manufacturing process flow and bring better products to market faster. At Karkhana.io, that’s exactly what we aim to do! Make manufacturing simple, scalable, and above all, stress-free.

If you’re building the next big thing in electronics, maybe it’s time to let your ideas meet the right factory floor.