Metal Casting Services

The Processes

Sand Casting

Gravity Die Casting

Pressure Die Casting

Investment Casting

Project Management Approach

1. Feasibility Study

2. Supplier Shortlisting

3. Cost Analysis & Quotation

4. Order Confirmation

5. QAP Approval from Customer

6. Supplier Selection & Technical Discussion

7. Material Procurement

8. Manufacturing

9. Quality Inspection

10. Dispatch

1. Feasibility Study

Understanding your requirements and assessing project scope

2. Supplier Shortlisting

Suppliers thoroughly evaluated to meet essential standards

3. Cost Analysis & Quotation

Offering competitive pricing with detailed quotes

4. Order Confirmation

Finalizing project scope and timelines

5. QAP Approval from Customer

Aligning quality assurance plans with the required specifications as per the standards

6. Supplier Selection & Technical Discussion

Ensuring the right supplier fit and technical alignment

7. Material Procurement

Sourcing high-quality materials for your parts

8. Manufacturing

Executing manufacturing processes according to defined specifications and process plans

9. Quality Inspection

Ensuring every part meets stringent quality benchmarks

10. Dispatch

Managing logistics to guarantee secure and on-time delivery

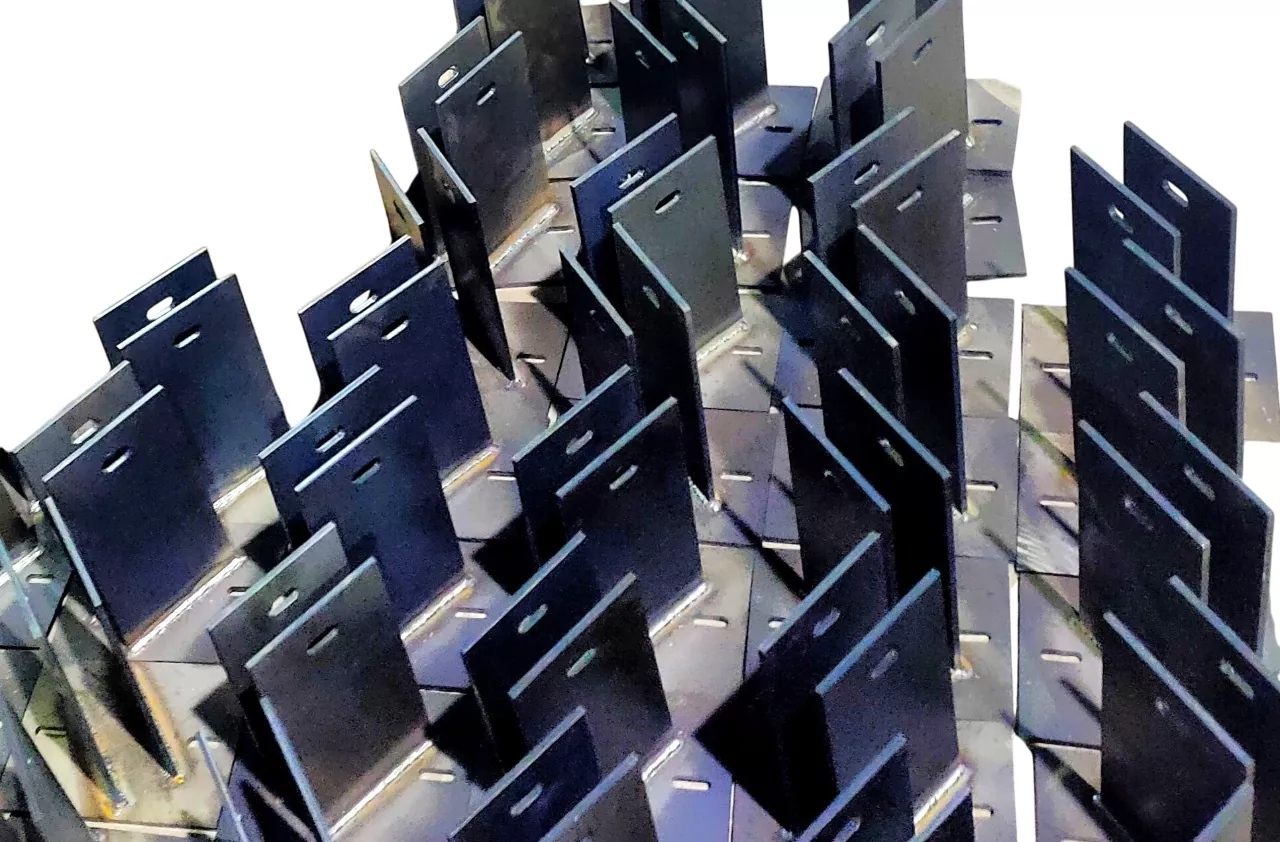

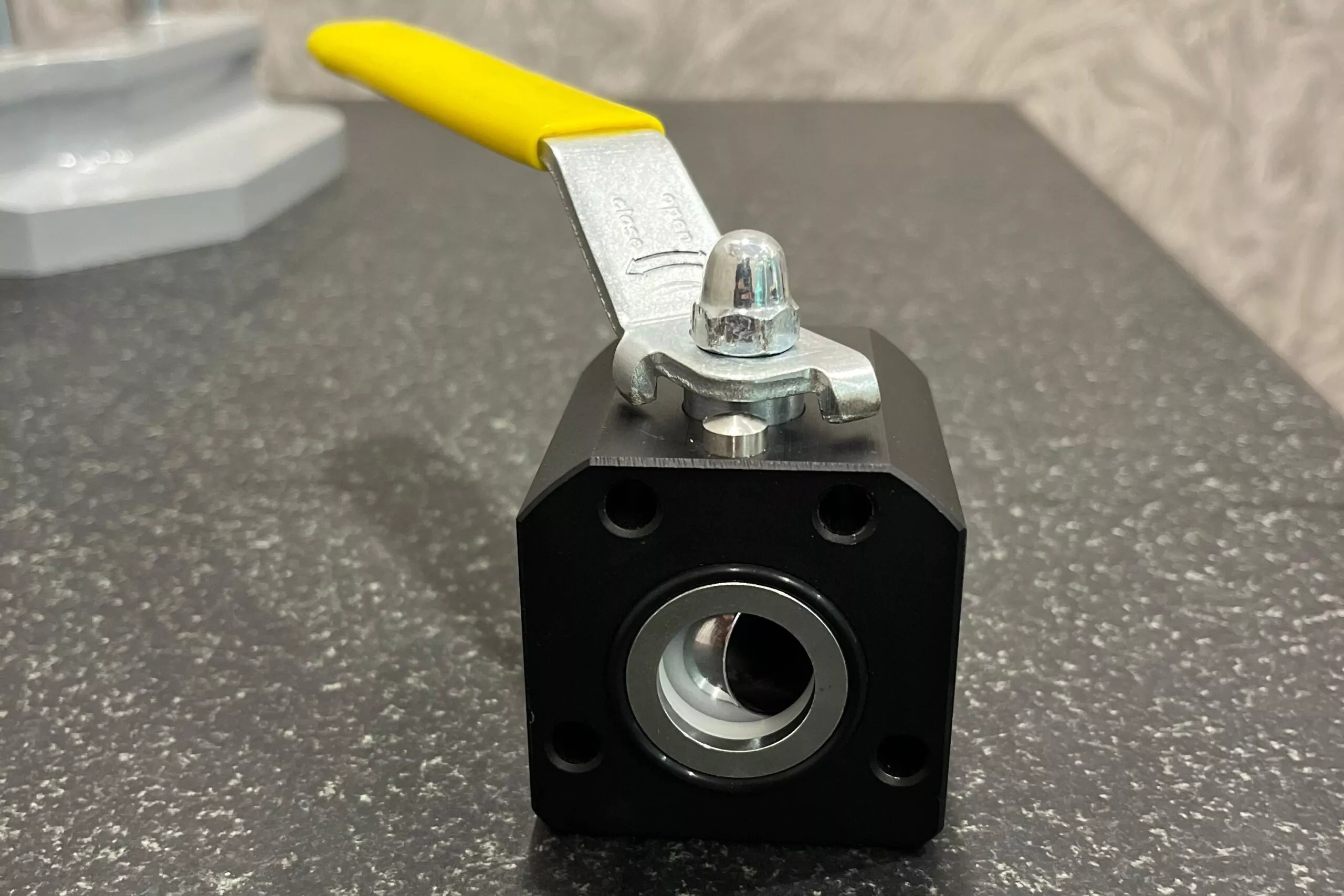

Product Gallery

Casting

Our Expertise

| Process | |

|---|---|

| Sand Casting | Component Range 0.2 to 120kg |

| Process | ||

|---|---|---|

| Gravity Die Casting | Weight 8 to 3500kg | Furnace Capacity 1000 to 2500kg |

| Pressure Die Casting | Machine Tonnage 120 to 350MT | Component Range 0.1 to 7kg |

| Single Component Casting Weight | Single Component Casting Dimensions | Minimum cross section thickness of casting | |

|---|---|---|---|

| Investment Casting | 10gm to 125kg | Maximum Diameter Upto - 700m | Stainless Steel - 2mm |

| Maximum Height Upto - 450mm | Alloy & Carbon Steel - 3mm |

Certifications

Industries Served

Energy

Delivering components built for power and durability

Oil & Gas

Creating parts that meet the demands of extreme environments

Industrial

Supporting robust and efficient industrial machinery

Aerospace

Meeting the strict standards required for aerospace applications

Related Case Studies

Expert Manufacturing for Your Needs – Start the Conversation

Frequently Asked Questions

What is the typical lead time for casting projects?

The typical lead time for casting projects at Karkhana.io depends on factors such as the complexity of the design, material choice, and production volume. Generally, the lead time ranges from 4 to 6 weeks for standard casting projects, including mold design, casting production, and testing. For more complex or customized projects, the timeline may vary, but we work closely with clients to ensure timely delivery while maintaining the highest quality standards.

What are the minimum and maximum sizes of parts you can produce through casting?

At Karkhana.io, we can produce casting parts ranging from a minimum size of 0.1 kg (for Pressure Die Casting) to a maximum size of 3500 kg (for Gravity Die Casting). The size range varies based on the specific casting process, including Sand Casting, Gravity Die Casting, Pressure Die Casting, and Investment Casting, providing flexibility to accommodate different project requirements.

How can I request a quote or place an order for casting services?

To request a quote or place an order for casting services at Karkhana.io, simply provide your part design details, including specifications such as material choice, dimensions, weight, and any specific requirements, along with any necessary technical drawings. Our team will review the details, prepare a detailed quote, and discuss the timeline and pricing with you. Once you approve the quote, we will proceed with the casting process, keeping you updated throughout the project.