If you have ever wondered how medical devices actually make it from an idea to something in a hospital room, then you’ve stepped into the world of medical device manufacturing. It’s exciting, high-stakes, and yes… incredibly complex. Every tiny mistake in the process could impact patient safety, so there’s zero room for error. Think heart monitors, diagnostic tools, or even wearable health gadgets.

This is where electronics manufacturing services (EMS) for medical devices come in. These are the teams that bridge the gap between designing a device and actually producing it at scale. And not just at scale, but also making sure that every device is reliable, compliant, and works perfectly. But trust us, it’s not as simple as pressing a button. There are a lot of challenges that come along the way, and today, we are going to dive into those!

If you’re curious about what is EMS industry is and how it fits into the broader electronics manufacturing industry, stick around. Today, we’re going to walk through the three types of EMS, the challenges they face in medical device contract manufacturing, and how companies like Karkhana.io are helping overcome them.

Table of Contents

ToggleWhat is EMS in Medical Devices?

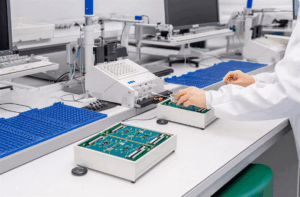

Let’s talk about the basics first. EMS, or Electronics Manufacturing Services, in the context of medical devices, is a specialized service. This is where providers handle parts or all of the medical device manufacturing process.

You can think of EMS providers as partners who don’t just assemble the circuit boards. They actually:

- Source specialized components for complex devices.

- Integrate electronics into functional systems.

- Test and inspect devices rigorously for safety and compliance

- Help with regulatory documentation to meet standards like ISO 13485 or FDA requirements

In simpler words, EMS providers make sure that the medical electronics manufacturing process is reliable and meets the highest standards. We are talking hospitals here, and cannot really afford to skip any quality measures.

Key Challenges Faced by EMS in Medical Device Manufacturing

Even with skilled teams and solid processes, the electronics manufacturing industry, especially for medical devices, is no walk in the park. Here are the main challenges:

-

Regulatory Compliance

It is no surprise that medical devices are some of the most heavily regulated products out there. This means there is usually meticulous documentation at every stage of the medical device manufacturing process. Even if you miss one detail, you could be looking at recalls or legal issues. So staying compliant is not optional; it’s the norm.

-

Quality Assurance

When it comes to medical electronics manufacturing, there is zero room for error. Literally zero. So every device has to be perfect. For this, EMS teams run rigorous tests, maintain full traceability, and make sure that the product meets the exact specifications. Because let’s be honest, in medical device manufacturing, this isn’t just about quality, it’s literally about patient safety.

-

Supply chain complexity

If you thought the supply chain would be an easy part, no! EMS parovers often juggle multiple suppliers, long lead times, and unpredictable global factors. If we talk specifically about medical device contract manufacturing companies, even a small supply disruption can halt the entire process. And well, that’s when you get delayed production and increased costs.

-

Rapid Technological Change

When talking of the medical industry, one cannot ignore the part technology plays in it. From IoT-enabled monitors to wearable devices and implantables, new technologies keep coming. So to keep up with that, EMS providers constantly upgrade their processes and train their teams, because, well, failing is not an option.

-

Cost and Time pressures

We have been in the industry for long enough to know how clients want their devices faster, cheaper, and better. And to balance speed, costs, and quality is one of the toughest challenges in medical device contract manufacturing. Like, for real, even a small delay or error can be pretty expensive!

Strategies EMS Providers Use to Overcome Challenges

So how do EMS providers stay on top of these hurdles? If you ask us, here is what works:

- Strong quality management systems help to maintain consistency in medical device manufacturing.

- Advanced technology and automation are a no-brainer at this point, as this is a sure-shot way to improve the overall efficiency in medical electronics manufacturing.

- Diversified supplies can actually help to reduce risks for medical device contract manufacturing companies.

- Teams are kept up-to-date on the latest standards in the medical device contract manufacturing industry.

- Streamlined workflows reduce cost and speed up the medical device manufacturing process.

Companies like Karkhana.io are doing exactly this, providing electronics manufacturing services EMS for medical devices that meet high compliance standards while keeping costs and timelines under control.

Also Read : The Future of Medical Device Manufacturing

Conclusion

The world of medical device manufacturing moves fast, comes with strict regulations, and leaves little room for error. That’s why electronics manufacturing services EMS for medical devices are absolutely crucial. They are the backbone that makes sure every step, from the medical device manufacturing process to supply chain management, compliance, and quality checks, runs smoothly.

For medical equipment manufacturers, teaming up with the right EMS partner like Karkhana.io means transforming ideas into devices that are safe, reliable, and ready for the market. Ultimately, the medical device contract manufacturing industry thrives because of these specialized EMS providers.