Robots are no longer just a futuristic concept they are an essential part of industries ranging from manufacturing and healthcare to aerospace and logistics. Every robot, regardless of its size or complexity, is built using a set of fundamental components that work together to perform tasks with speed, accuracy, and consistency. Understanding these core parts is crucial for anyone looking to design, build, or integrate robotics into real-world applications.

In this blog, we’ll explore the five main parts of a robot—end effector, robot arm, actuator, sensors, and controller. Each of these components plays a critical role in how a robot functions, interacts with its environment, and delivers precise results. By the end, you’ll have a clear understanding of how these elements come together to create the smart machines shaping our future.

Table of Contents

ToggleThe 5 Main Parts of a Robot

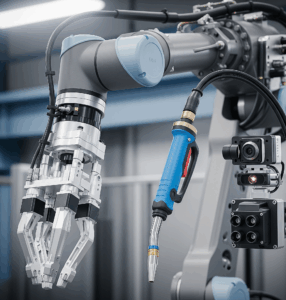

1. End effector

End effectors are the tools that are attached to the end of the robot arm. The end effector enables the robot to interact with its task and to do useful work. The types of end effector includes:

- Gripper: It is a device that enables the robot to pick-up and hold objects. The different types of gripper include vacuum grabber, biomimetic hand, humanoid hand, gripping tentacle, high-speed claw.

- N Process Tools: It consists of tools like drills, grinding wheels, cutting wheels, laser and water jet cutters, welding torches, spray painting tools, glue application tools, etc.

- Sensors: A sensor can be attached to a robot as a programmable sensor orientation device. This is useful for applications like robotic inspections. Understanding robot parts and their functions helps in choosing the right end effector for specific tasks.

2. Robot Arm

Robotic Arm is composed of links and joints. Links are the rigid sections that make up the mechanism and joints are used to connect two links. It works in a similar way as a human arm.

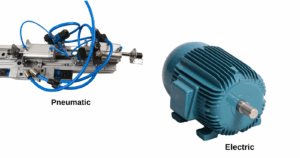

3. Actuator

An actuator is a device that causes motion of robot arms and end-effectors. Majority of actuators produce two types of motion – linear and rotary. They produce this kind of motion by converting input energy into mechanical motion. The common types of actuators are hydraulic, pneumatic and electric. The actuator is one of the key components of robots that determines how effectively a robot can move and perform tasks.

4. Sensors

These devices are used to capture data about the robot itself and the surroundings of the robot. The devices that capture data about robots are called internal sensors and the data captured includes position, velocity, acceleration, motor torque, etc. The devices that capture data of surroundings are known as external sensors. The data captured by external sensors include the view of the environment (captured using cameras), range (captured using IR, laser, ultrasonic, etc), force, contact and proximity, etc.

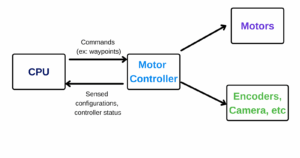

5. Controller

Controller is a device that performs analog-to-digital and digital-to-analog conversion. Controller takes digital inputs from the CPU and computes analog signals for motors to achieve desired output. It also converts reading from sensors to digital signals and sends it to the CPU. Most controllers also perform other operations like calibration, PID control, filtering, temperature regulation, trajectory interpolation, etc. A controller, along with sensors, actuators, and the robot arm, forms the basic parts of a robot that enable it to function seamlessly.

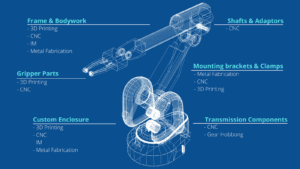

Robot parts manufactured by Karkhana.io

Karkhana.io has capabilities to manufacture custom parts and subparts of robots. We work with startups, SMEs and enterprises from building prototypes till the production of the robot. Our unique product platform (app.karkhana.io) makes it easy for customers to submit RFQs within clicks, get quotations within days, get instant DFM feedback, get design and manufacturing counsel and track status of production and shipment.

Our flexible manufacturing services enable us to service client orders of all sizes from small batches to large volumes. We also help many of our clients in solving complex product assembly and localization problems.

We have an extensive, cutting-edge experience with all electronic manufacturing services like 3d printing, Sheet metal fabrication, Injection moulding, and Vacuum casting.

Trusted Electronic Manufacturing Services

From prototype to production — precision EMS solutions for your business.

Request a QuoteWe cater to every manufacturing need across industries like Aerospace, Automation, Automobile, Defence, Drone, Energy, EVs, FMCG, General Engineering, Medical, Oil & Gas, Pharma, and Robotics.

Partner with us to bring speed to your manufacturing.