Welcome to Karkhana.io, your trusted partner in flexible and scalable manufacturing solutions. In this blog, we will explore the key differences between B Tooling and D Tooling in tablet manufacturing and discuss their respective applications. Discover how Karkhana.io can provide tailored manufacturing solutions to meet your tablet production needs.

Table of Contents

ToggleUnderstanding B Tooling

B Tooling is a widely used tablet tooling standard in the pharmaceutical industry. It is characterized by a round-shaped die with a concave top and bottom punch. The die diameter, punch head, and tablet thickness are standardized based on specific sizes and configurations.

B Tooling is commonly used for the production of conventional tablets with flat or slightly convex faces. It offers versatility in tablet design, allowing for a wide range of tablet sizes and shapes. B Tooling is ideal for high-volume tablet manufacturing and is compatible with various tooling of tablet compression machine standards, including the B Tooling compression machine widely adopted in the industry.

Exploring D Tooling

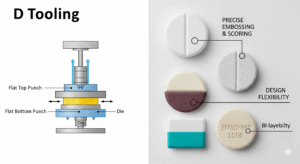

D Tooling, also known as “European Tooling,” is another popular standard for tablet manufacturing. Unlike B Tooling, D Tooling features a die with a flat top and bottom punch. The shape of the tablet is determined by the die cavity, which can be customized according to specific requirements.

D Tooling is often preferred for tablets with special designs, such as scored or bi-layered tablets. The flat faces of D Tooling allow for precise embossing and scoring, enabling easy tablet division or identification. It offers flexibility in tablet design and is suitable for small-scale or specialized tablet production where different types of tooling in compression machine are applied.

Key Differences and Applications

- Tablet Design: B Tooling is well-suited for conventional tablets with flat or slightly convex faces. It allows for a variety of tablet sizes and shapes. D Tooling, on the other hand, is preferred for tablets with special designs, such as scored or bi-layered tablets, thanks to its flat faces.

- Production Volume: B Tooling is commonly used for high-volume tablet manufacturing due to its standardized sizes and compatibility with a wide range of tooling of tablet compression machine.

- Flexibility: B Tooling provides versatility in tablet design, making it suitable for a broad range of applications. D Tooling offers flexibility in creating tablets with unique features, such as scoring or embossing.

Both fall under the types of tooling in compression machine standards, making the choice between them critical for different production needs.

Discover Karkhana.io’s Tablet Manufacturing Solutions

Choosing the right tablet tooling is crucial for successful tablet manufacturing. B Tooling and D Tooling have distinct characteristics and applications. Partner with Karkhana.io to optimize your tablet manufacturing processes. Karkhana.io, with its extensive manufacturing network, can provide tailored solutions to meet your tablet production requirements.

Contact us today to leverage our expertise and drive efficiency and excellence in your tablet production. Fill out the form below to explore how Karkhana.io’s capabilities can enhance your tablet production.

Frequently Asked Questions:

1: What is the main difference between D Tooling and B Tooling?

The main difference lies in size and application. B Tooling is smaller and suited for high-volume production, while D Tooling is larger and often used for specialized tablets like scored or bi-layered ones.

2. What is a B Tooling compression machine?

A b tooling compression machine is designed to accommodate B Tooling punches and dies. It is commonly used in large-scale pharmaceutical manufacturing due to its compatibility and efficiency.

3: Why is tooling important in a tablet compression machine?

The tooling of tablet compression machine directly impacts tablet shape, size, and quality. Correct tooling ensures uniformity, reduces defects, and supports efficient mass production.

4: What are the types of tooling in compression machines?

The common types of tooling in compression machine setups are B Tooling, D Tooling, and their variations (BB, DB). Each type differs in punch diameter, die size, and suitability for different production scales.

5: How do I choose between D Tooling and B Tooling?

The choice depends on your production goals. For large-scale, conventional tablets, B Tooling is ideal. For specialized, embossed, or bi-layered tablets, D Tooling offers better flexibility.