The enclosure of your EEE or IoT device will serve the end consumer for years and will protect the device from water ingress, corrosion, harsh weather conditions, high impact, electric shocks, and other situations in most cases.

The durability and accessibility of your device are directly proportional to its success, and challenges with the enclosure can result in opportunity loss amounting to a large portion of your target market share. This is why understanding the electrical enclosures manufacturing process is essential before making key decisions.

Selecting the right IoT enclosure, on the other hand, can increase its accessibility and market attraction at the same time. In this blog, we cover the five most important things you must take care of before manufacturing your EEE or IoT enclosure and exploring opportunities in the electrical enclosures market.

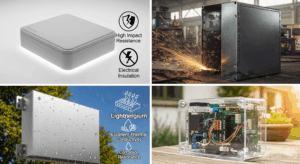

#1 Type of material based on factors like thermal resistance, weatherproof factor, durability, and others

There are a lot of options in terms of materials like ABS plastic, steel, aluminium, polycarbonate, and others. Your decision to choose the material should be based on multiple considerations, including:

- Electrical insulation requirements

- Thermal and chemical resistance

- Corrosion and scratch resistance

- EMI/RFI shielding

- Internal/external end-use case

- Weight

- Machinability

- Weatherproof factor

- Durability

- And others

One important factor is thermal insulation for electrical enclosures, as it directly affects device performance and longevity.

#2 IP, NEMA, UL or other ratings based on the end use-case

Compliance is something you cannot ignore, and you might have to comply with different rules based on where you sell your device.

Some of the most common compliance certifications that you must consider are:

- IP certification for water and dust ingress

- NEMA rating for water and dust ingress and durability from specific weather conditions

- UL rating

- RoHS compliance

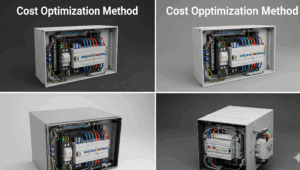

#3 Total cost of ownership and type of manufacturing process (Sheet metal, 3D printing, and others)

Cost optimisation is something you cannot ignore in order to be competitive in the market. One of the most significant factors that influence cost is the electrical enclosures manufacturing process. You can choose from 3D printing, sheet metal fabrication, injection moulding, and others.

You must consider the following:

- Machinability of the material with the specific manufacturing process

- Cost of materials

- Scalability of the manufacturing process

- Access to and availability of expert technical know-how for the specific process

- Scope for future changes

- And other factors

#4 Design that separates the aesthetic look and feel from your competitors

At the end of the day, the design is a major deciding factor for the end customer. The device’s design should be planned and accessed before you start manufacturing.

The manufacturing process you choose, materials, shape, components of the device, and other factors influence the design. Detailed DfM feedback can help you do a detailed analysis of the design. It can help you create a design with an edge over the competition both from a usability and aesthetics point of view.

#5 Considerations for components and scope for future modifications (based on specific use cases)

Your IoT enclosure should account for the right balance of space for device components and future changes that you might have to consider. Keeping extra and limited space for components and future considerations are both challenges that need to be addressed before we start manufacturing.

How can Karkhana.io help manufacture great enclosures for your EEE or IoT devices?

We at Karkhana.io understand the challenges and questions businesses face while designing and manufacturing IoT enclosures. As an electronics manufacturing services provider, we help them supplement their decisions with inputs from our vast network of manufacturers, engineers, designers, and other manufacturing experts.

Our digital manufacturing platform is built to address the challenges of companies planning to manufacture IoT enclosures. It gives you access to instant quotations for different manufacturing processes, end-to-end project management, DfM feedback via our expert engineers, regular QC, audits of suppliers, logistics, payments, sharing project files within your organisation on the platform dashboard, viewing your CAD files, and more.

Looking for ways to level up the manufacturing of your electronic enclosure box? Start by registering on our digital platform.

Frequently Asked Questions:

Q1. What is the electrical enclosures manufacturing process?

The electrical enclosures manufacturing process involves choosing the right materials and fabrication methods, such as sheet metal, 3D printing, or injection molding, to ensure durability, thermal insulation, and compliance with IP, NEMA, or UL standards.

Q2. Why is thermal insulation for electrical enclosures important?

Thermal insulation for electrical enclosures protects the internal components from overheating, enhancing device performance, reliability, and longevity.

Q3. How does the electrical enclosures market influence product design?

The electrical enclosures market demands products that balance durability, aesthetics, and compliance, encouraging manufacturers to innovate in materials, design, and manufacturing processes.

Q4. How can an electronics manufacturing services provider assist in enclosure production?

An electronics manufacturing services provider offers expertise in materials, manufacturing processes, DfM feedback, and quality control to optimize enclosure performance and cost-efficiency.

Q5. What factors should be considered when selecting an IoT or EEE enclosure?

Factors include material type, thermal insulation for electrical enclosures, IP/NEMA/UL ratings, manufacturing process, cost, design aesthetics, and space for components and future upgrades.