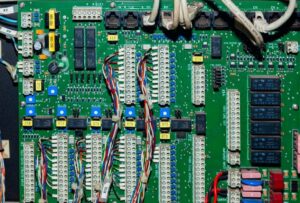

If you’ve ever opened up an electronic gadget and stared at the tiny maze of copper lines, chips, and components on the board, you already know what a PCB means to the life of an electronic product. But what most people don’t realize is this: the quality of that PCB doesn’t depend only on good design or good soldering. Instead, it actually depends on something deeper, something more standardized.

And guess what? That “something” is IPC standards. Whether you are planning on building a consumer device, a medical system, or an industrial controller, IPC standards quietly decide whether your PCB will be reliable, durable, and ready for real-world use. And yes, we will walk you through what IPC standards are, why they exist, some of the key ones to know (especially for design), how they affect manufacturing and reliability, and what can go wrong if you ignore them.

So let’s begin!

Table of Contents

ToggleWhat Are IPC Standards for PCB and Why Do They Exist?

You can think of IPC standards as a globally recognized rulebook for designing, building, and inspecting printed circuit boards (PCBs). It basically brings together experts from all over the electronics world. Whether it is designers, manufacturers, or inspectors, they all collaborate to publish standards that set the bar for quality, reliability, and process control.

Sounds pretty simple, right? When people talk about IPC standards for PCB, they are actually talking about these guidelines. This way, everything can be built correctly and consistently, no matter where they come from.

These standards exist because:

- Consistency across the board is a non-negotiable. Without IPC standards, a PCB made in one factory might be wildly different from a PCB made somewhere else.

- It brings better communication among the teams. Like if the designer says, “build to IPC standards”, the manufacturer knows exactly what that means.

- By following the IPC standards for PCB, you also reduce the chances of failure.

- It also makes it globally compatible. Meaning if you are designing in one country and manufacturing in another (or selling globally), IPC gives you a common benchmark.

So in short, IPC standards exist for you, work for you, not against you!

Key IPC Standards Relevant to PCB Design

When people talk about IPC standards for PCB design, what they usually mean is a core set of design rules and guidelines that ensure three things: manufacturability, reliability, and consistency. Below, we have added all you need to know about these guidelines:

| IPC Standard | Design Focus | Why It’s Important for Designers |

| IPC-2221 | Generic PCB design rules | Sets the baseline for layout, trace width, spacing, and via design. If you follow this, your board is more likely to be manufacturable at any factory. |

| IPC-2222 | Rigid board design | Contains rules specific to rigid PCBs (rigid is the most common kind). Helps designers ensure structural robustness. |

| IPC-2223 | Flexible board design | For flex or rigid-flex PCBs (think bendable electronics, wearables, or sensors) tells you how much you can bend, how to place vias, etc. |

| IPC-2581 | Data exchange standard | Helps exchange design data cleanly between CAD tools and manufacturing. Minimizes misinterpretation between designers and manufacturers. |

| IPC-4101 (and 4100 series) | Material/substrate specification | Guides designers on what base materials (laminates, prepregs) to pick, based on electrical and mechanical needs. |

These are the core standards when we talk about IPC PCB design standards. When your design team follows them, you are much more likely to produce a board that is easy to manufacture and that meets the quality bar you set.

Potential Risks & Challenges If IPC Standards Are Ignored

Okay, now we are reaching the not-so-fun part. Like, what if you decide to ignore IPC standards for PCB? Imagine you’ve spent months designing your circuit board, sourcing components, setting up timelines, and then things go sideways simply because IPC standards weren’t followed properly. It sounds dramatic, but it happens more often than you think.

Here are some potential risks that you should be aware of:

Risk 1: Unpredictable Quality And Defects

Without the IPC standards guiding the design and the whole manufacturing process, every outcome is no less than a gamble. Yes, maybe the solder joints seem strong, but hey, maybe they are not. Maybe the board tolerances are right… or maybe they’re just “close enough.” And that uncertainty shows up later as random failures, unstable performance, or issues that are impossible to debug.

Basically, you just end up with electronics that work until they don’t, and that’s not something you would want in the hands of your customer.

Risk 2: Communication Breakdown

Designers think of one thing, while manufacturers think of another. Here, a missing IPC reference means everyone is operating on their own definition of “good quality”. And guess what happens when assumptions replace standards? Well, that leads to incorrect builds, design mismatches, and a lot of awkward calls that start with, “So, this didn’t turn out the way we expected it to.”

Risk 3: Higher Rework Costs

If a board comes back with defects because the right standards were not followed, someone will have to work overtime to fix that. And we all know that rework takes time, money, and patience. None of these things are usually in excess during production.

In fact, there are some cases where the defects are so deep (like layout flaws) that the whole batch has to be scrapped and redesigned. That’s the kind of pain every hardware team wants to avoid.

Risk 4: Lower First-Pass Yield

First-pass yield is basically the number of boards that pass all the tests on the first try. When IPC standards are not part of the designing or assembly workflow, the first pass yield almost always drops.

So, in other words, more boards fail inspection right from the start. That slows down delivery, stretches timelines, increases pressure on the team, and yes, increases cost again. And that’s not a win-win for anyone!

Risk 5: Limited Scale And Global Risks

Let’s be honest: Scaling a hardware product isn’t as simple as just making more units. If you have been in the industry for even a short period of time, you would know how, ow as production grows and new factories or countries get involved, consistency becomes everything.

In addition to that, if your designs and documentation are not in sync with IPC, then manufacturers in other regions might not even accept the project. This way, scaling won’t be your milestone, but a barrier!

Risk 6: Regulatory Or Compliance Issues

This one really matters, especially if you are in medical electronics, automotive, aerospace, industrial automation, or basically anything that goes through third-party audits. Many quality certifications expect your PCB manufacturing and assembly to follow (or at least reference) IPC.

And if they don’t, then you will end up with more issues than you started with. Whether it is compliance issues, audit flags, or delays in product approval, all of that will be on your shoulders!

Final Thoughts

To sum it up, we can say that ignoring IPC standards isn’t just “taking a shortcut.” It’s like building a house without agreed-upon construction rules. So yes, you might save up some time upfront, but you are actually signing up for much bigger problems later. IPC standards for PCB are not optional if you care about reliability, quality, and repeatable manufacturing. They’re your safety net. They make design and production predictable, scalable, and globally compatible.

And well, when it comes to PCBs, IPC isn’t about perfection. Instead, at Karkhana.io, we believe that it’s about predictability, reliability, and never leaving quality to chance. Reach out for your concerns, and we will make sure we bring solutions that align with global standards and your wishes.

Frequently Asked Questions

1. What is the IPC standard for PCB assembly?

IPC standards for PCB assembly are global guidelines that define how printed circuit boards should be manufactured, soldered, and inspected to ensure reliability and quality. The most widely followed is IPC-A-610, which outlines acceptability criteria for assembled boards.

2. What are the IPC standards for PCB inspection and what defects are commonly found?

PCB inspection typically follows IPC-A-610 and IPC-600, covering visual criteria, workmanship, and board-level quality. Common defects include solder voids, insufficient solder, misalignment, bridging, lifted pads, and component damage.

3. What are the advantages of interprocess communication?

Interprocess communication (IPC) enables faster data exchange, improved system performance, better resource sharing, and smoother coordination between processes within an application or OS.

4. What is the main purpose of the communication process?

The main purpose is to transfer information clearly and efficiently so that the receiver understands and responds as intended—whether in systems, organizations, or human interaction.

5. Which IPC standards are commonly used in PCB assembly?

Key IPC standards include IPC-A-610 (acceptability of assemblies), IPC-J-STD-001 (soldering requirements), IPC-7711/7721 (rework and repair), and IPC-7351 (land pattern design). These ensure consistent manufacturing quality across the industry.