If you have ever looked at a circuit board and wondered how all those tiny components manage to fit so neatly together, the answer lies in the brilliance of SMT technology. And if you’ve seen older boards with little legs poking through holes, that’s what we call TMT.

In simple terms, SMT (Surface Mount Technology) and TMT (Through Mount Technology) are two different ways of assembling components on a printed circuit board (PCB). And well, both have their place in electronics manufacturing, so the choice ultimately depends on your product’s design, size, and durability needs.

At Karkhana.io, we work with both. On one hand, we have the SMT process that handles modern miniaturized components, while TMT steps in for parts that need a bit more mechanical strength or size tolerance. So let’s break it down from understanding what SMT technology is, to learning about the difference between SMT and TMT, and finally, how you can pick the right partner for your manufacturing needs.

Table of Contents

ToggleWhat is SMT Technology?

You’ve probably heard the term “SMT” thrown around in electronics, but what is SMT technology exactly? In simple words, SMT technology is a method of mounting electronic components directly onto the surface of a PCB, so no holes are required! You can think of it like placing tiny Lego pieces on a flat surface, instead of plugging them through holes.

So it’s fast, compact, and efficient. That is why almost every modern gadget you use, from smartphones to smartwatches, they all have these same SMT-assembled boards inside.

But what is the purpose of SMT?

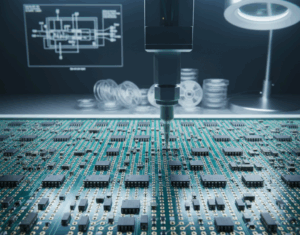

The main purpose of SMT is basically to make electronics smaller, faster, and more efficient to produce. Thanks to SMT process automation, thousands of components can be placed on a PCB every minute by high-speed pick-and-place machines, which we call SMT machines.

When you question what is an SMT machine, you can imagine a robotic system that picks components from reels, places them precisely onto the board, and then sends the board through a reflow oven to secure them.

So the SMT process usually involves:

- Applying solder paste on the board.

- Placing components with an SMT machine.

- Reflow soldering to attach them permanently.

- Inspection and testing to ensure everything’s perfect.

At Karkhana.io, these steps happen seamlessly on high-speed SMT lines. This way, we deliver accuracy, efficiency, and consistent quality at all times!

What is TMT Technology?

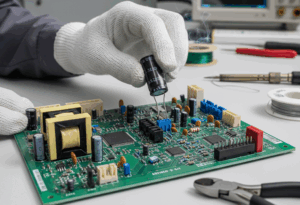

Now that we’ve understood what is SMT technology, let’s talk about its counterpart, TMT, which is also known as Through-Hole Technology. Here, component leads or pins are inserted into drilled holes on the PCB and soldered from the opposite side.

If SMT is all about mounting things on the surface, TMT is more of a through-mounting style. This is usually an old-school, hands-on way of building electronics that still holds its ground today. You’ll often spot TMT in things like power supplies, transformers, and connectors. Basically, any large component that gives off heat or needs to stay extra secure.

Unlike the fully automated SMT process, TMT usually needs a bit of human touch or wave soldering. It may take longer, but it gives you stronger, sturdier bonds. So it is literally perfect for parts that have to handle pressure, stress, or constant movement.

What is the Difference between SMT and TMT

Now, coming to the big question: What is the difference between SMT and TMT?

| Feature | SMT Technology | TMT Technology |

| Mounting Style | Components mounted directly on the PCB surface | Components inserted through drilled holes |

| Automation Level | Fully automated SMT process using SMT machines | Semi-automated or manual |

| Component Size | Very small, lightweight | Larger, bulkier |

| Production Speed | Extremely fast | Comparatively slower |

| Durability | Electrically reliable, with less mechanical strength | High mechanical strength |

| Applications | Phones, wearables, laptops, IoT devices | Automotive, heavy-duty equipment, and power circuits |

The difference between SMT and TMT ultimately comes down to what your product needs. So if you are designing a sleek, compact gadget, SMT technology wins, hands down! But if your board will face vibration, heat, or high mechanical load, TMT might be the better choice. Here, what we do is we use SMT for smaller components, and TMT for heavy connectors or transformers.

When to Use SMT vs TMT?

Now that you know what an SMT machine and other SMT components are, let’s move ahead! Choosing between SMT and TMT isn’t always black and white. So a lot of it actually depends on the design of your product, manufacturing goals, and the budget. So here is a simple guide for you:

Use SMT when:

- You need compact PCBs and lightweight assemblies.

- Your production volume is high, so automation is what will save your business by cutting down the costs.

- Your device needs high-speed performance with multiple micro-components.

- You want a faster turnaround time using a fully automated SMT process.

For example, if you are producing wearables, then trust us, SMT’s precision and scale are unbeatable!

Use TMT when:

- Your components are physically large or require strong mechanical bonding.

- The board will face stress, vibration, or high temperatures.

- You are working on prototypes or low-volume runs.

A good example would be industrial controllers or automotive ECUs. This is usually where TMT is used for connectors, while SMT takes care of the smaller ones.

How to Choose the Right Manufacturing Partner

Whether you go for SMT or TMT, what truly defines your product’s success is how well the manufacturing process is carried out. And well, a capable partner doesn’t just assemble parts. A good one actually makes sure every step, from sourcing components to assembly and testing. All of this happens seamlessly under one roof with tight quality checks in place.

That’s exactly where Karkhana.io stands out!

We offer end-to-end electronics manufacturing services. Our team covers everything from the SMT process and TMT assembly to box builds, testing, and even supply chain management.

This is what you get when you choose us:

- We have the expertise you need.

- Our high-speed SMT machines keep accuracy as their priority.

- We do quality checks for you like never before.

- Whether it’s 100 units or a million, the process stays smooth and reliable

Frequently Asked Questions

1.Why do we use SMT?

The main reason is that it allows manufacturers to build smaller, faster, and more powerful electronics. The SMT process makes it possible to place thousands of components on a single board quickly using SMT machines.

2. What is SMT work?

When someone says “does SMT work,” what they mean is the assembly part of PCBs using SMT technology. It involves applying solder paste, placing components, and running the board.

3. What is the function of SMT?

The function of SMT is to place components right on the PCB’s surface. And this not only saves space but also improves how signals travel across the board.

4. Who can use SMT?

Anyone designing or manufacturing electronic devices, whether its a startup building IoT gadgets to large-scale OEMs, SMT technology fits all!

5. Why SMT is important?

SMT technology matters more than we realize. It’s what makes our gadgets smaller, smarter, and faster. Without it, compact smartphones, sleek wearables, and efficient industrial systems wouldn’t exist.