If you’ve ever wondered how your smartphone, laptop, or even your smart fridge works, the magic often lies in a little thing called a PCB. But what is PCB in electronics, and why is it so essential? To put it simply, a PCB, or printed circuit board, is the backbone of almost every electronic device you own. In short, it connects and supports various electronic components like resistors, capacitors, and microchips. This way, the electricity flows smoothly and powers up your gadgets.

In this article, we’ll break down everything about types of printed circuit boards, their uses, and even give you a sneak peek into how to make a printed circuit board at home or in a lab. So without further ado, let’s get started!

Table of Contents

ToggleWhat Is PCB and Its Use?

So let’s start with the basics: What is PCB and its use?

Basically, a printed circuit board (PCB) is just a flat board that connects all the parts of an electronic device. There are tiny pathways carrying power and signals from one component to another.

And well, PCBs are everywhere, we mean, look around! Literally from small gadgets like watches to large-scale industrial machines, they provide stability, organization, and reliability, and even ensure that your electronics don’t turn into a messy jumble of wires. It would be safe to say that all this assembling of complex electronic devices would be nearly impossible without a PCB.

How to Make a Printed Circuit Board?

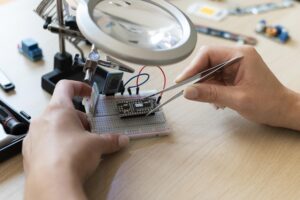

You might be thinking, “This sounds cool, but how do people actually make these boards?” Well, while factories use advanced machines, the basic process isn’t that hard to understand. Here is how the process goes:

Step 1: Design the layout

Step 2: Print the design on a copper board

Step 3: Etch away extra copper

Step 4: Drill holes

Step 5: Components are placed and connected to the copper traces.

Types of Printed Circuit Boards (PCB)

Now comes the part where we tell you about the different types of PCB boards. Understanding these will help you choose the right one for your project or understand the technology behind your gadgets.

-

Single-Sided PCBs

Single-sided PCBs are literally the simplest form of PCBs. They have a single layer of conductive copper on one side of the board, with components placed on the other side.

Uses: LED lights, calculators, power supplies.

Pros: Cheap, easy to design, perfect for simple devices.

Cons: Not suitable for complex circuits.

-

Double-Sided PCBs

As the name suggests, double-sided PCBs have conductive copper layers on both sides of the board. This type is usually used in more advanced devices such as amplifiers or power meters, where tiny holes (vias) connect the top and bottom layers.

Uses: Amplifiers, test equipment, and LED displays.

Pros: More space for circuits, flexible designs.

Cons: Slightly costlier, harder to produce than single-sided.

-

Multi-Layer PCBs

When your device demands very complex circuits, multi-layer PCBs come into play! These have three or more copper layers stacked together, which are then separated by insulation.

Uses: Smartphones, laptops, servers.

Pros: High performance, saves space, reduces interference.

Cons: Expensive and complex to manufacture.

-

Rigid PCBs

Made from fiberglass, these are solid, inflexible Rigid PCBs which are used in most of the electronics you see every day. What makes them special is their strength and durability, which make them great for devices that do not require bending.

Uses: TVs, desktops, industrial machines.

Pros: Strong, durable, long-lasting.

Cons: No flexibility for foldable devices.

-

Flexible PCBs (Flex PCBs)

We are witnessing an era where gadgets keep getting thinner and thinner, all thanks to flexible PCBs. They are made from flexible plastic materials so they can bend, fold, or twist.

Uses: Wearables, cameras, medical devices.

Pros: Lightweight, fits in compact devices.

Cons: Costlier and delicate compared to rigid PCBs.

-

Rigid-Flex PCBs

Bring in the best of both worlds, rigid-flex PCBs combine the strengths of rigid and flexible PCBs. Here is more about them:

Uses: Aerospace systems, high-end smartphones, and medical equipment.

Pros: Saves space, reduces connectors, and is versatile.

Cons: Expensive, requires precise design.

-

High-Frequency PCBs

Some electronic devices, especially in communication systems, require materials that can allow high-speed signal transmission without loss.

Uses: Telecom, radar, satellite systems.

Pros: Stable at high frequencies, low signal loss.

Cons: Expensive materials and manufacturing.

-

Metal-Core PCBs

Some electronics generate a lot of heat, which is exactly where metal-core PCBs are used. The boards here have a metak layer, which is usually alluminkum to dissipate the heat effectively.

Uses: LED lighting, power converters.

Pros: Excellent heat management, longer lifespan.

Cons: Costlier and heavier than regular PCBs.

-

Ceramic PCBs

Ceramic PCBs are designed for extreme environments. Basically, all the high-frequency applications where you need heat resistance and durability, these PCBs come in handy.

Uses: Aerospace, military, industrial sensors.

Pros: Very heat-resistant, durable.

Cons: Extremely expensive, niche usage.

There you go! That was a list of types of printed circuit boards that can help you understand them.

Summary: Applications of Different Types of PCB Boards

Let’s break down where you’ll find these different types of PCB boards:

Single-Sided PCBs: Calculators, simple power supplies, toys

Double-Sided PCBs: Amplifiers, industrial machines, LED displays

Multi-Layer PCBs: Smartphones, laptops, medical equipment

Rigid PCBs: TVs, desktop computers, home appliances

Flexible PCBs: Wearables, cameras, foldable devices

Rigid-Flex PCBs: Aerospace systems, high-end smartphones, medical instruments

High-Frequency PCBs: Telecom systems, radar devices

Metal-Core PCBs: LED lighting, power converters

Ceramic PCBs: Military electronics, high-temperature applications

Also Read : Top PCB Manufacturers in India 2025

Conclusion

PCBs might seem like simple boards at first glance, but they are the foundation of modern electronics. From single-sided PCBs in simple devices to multi-layer and rigid-flex boards in advanced technology, the variety is vast. At Karkhana.io, we don’t just stop at explaining what is PCB in electronics, but we help hardware teams go from idea to reality.

And by understanding the different types of PCBs, the applications of all types of printed circuit boards, and even the basics of how to make a printed circuit board, you can gain insight into the inner workings of the devices.