For any hardware founder or OEM scaling in India, the question is no longer “Should we localize?” it’s “How much should we localize, how soon, and where should we start?”

Over the past five years, the Indian electronics manufacturing stack has transformed in great ways! There is more capability, better infrastructure, and stronger partnerships than ever. But we still can’t say it’s a perfectly connected system. There are gaps, dependencies, and trade-offs that only reveal themselves when you actually start building at scale.

We are bringing you this guide, which breaks down what’s truly local, what still leans global, and what that means for you when you are taking a hardware product from concept to customer.

Step One: Stop Asking “Can This Be Made in India?”

The better question is:

“Which parts of my product should be made here to optimize time, cost, and control?”

And honestly, the answer is rarely black and white. It’s not about going 100% local or 100% global. It’s about strategically partitioning your supply chain. This can happen by keeping certain production states in India while leveraging global sourcing where it makes more sense.

Below, we will break it down layer by layer, based on what the founders who want to scale hardware in India typically encounter.

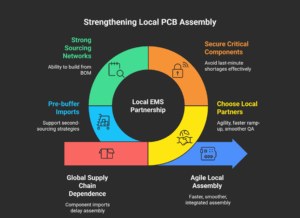

PCB Assembly: Local and Strong

What’s local: India now has some solid PCB assembly services India, that cover SMT, THT, and full box build capabilities. And guess what? We at Karkhana.io can handle medium to high volumes with absolute traceability, functional testing, and even integrated end-to-end assembly.

What’s not: Around 85–90% of components are still imported. It happens mainly in China, Taiwan, and Malaysia. This means even “local” PCBA work is still tied to global supply chain timelines.

Founder Insight:

- You need to choose local EMS partners for agility, faster ramp-up, smoother QA, and integration with custom electronic enclosures.

- Also, make sure to lock in critical path ICs and passives early so you can avoid last-minute shortages.

- Work with electronic product development companies in India that have strong sourcing networks. Believe us, you don’t just need the ability to build from your BOM list.

- Last but not least, you need to get in touch with EMS partners who can pre-buffer imports and support second-sourcing strategies so you’re never stuck waiting on a single supplier.

Enclosures, Plastics, and Sheet Metal: Strong Local Options, but Design Matters

What’s local: With reliable tolerances, premium finishes, and cost-effective production, you can actually find high-quality injection molding, sheet metal fabrication, powder coating, and CNC machining, right here in India. This can be ideal if your volumes justify the tooling costs. But don’t forget to read the tricky part ahead!

What’s tricky:

Here is what’s tricky:

- Low-volume or frequently changing designs fall short on the tooling costs.

- For cosmetic-grade plastics that are used for consumer electronics, you may need to import raw materials, or, well, extra rework.

Founders Insight:

- If your industrial design is locked and finally stable after 2-3 iterations, then local tooling makes sense.

- You should design with local DFM standards in mind. Details like wall thickness and rib structure can literally make or break feasibility.

- Another thing is to stick to metric fasteners and avoid exotic surface finishes, unless you have a strong reason to back it up.

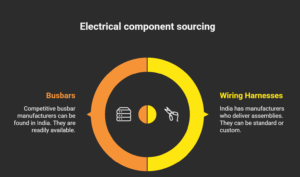

Wiring Harnesses, Busbars, and Battery Packs: Semi-Local, Needs Integration

What’s local: India actually has a growing base of wiring harness manufacturers India who can deliver both standard and custom assemblies. For busbars, you’ll find competitive busbar manufacturers in India.

What’s not:

- The battery cells themselves are imported mostly from countries like China or Korea.

- Specialized connectors like JST or Molex, and some crimp terminals, are also dependent on the import.

- If we talk about BMS ICs and protection circuits, they also often have long lead times.

Founders Insight:

- Work with a wire harness company in India that can also manage battery integration.

- For safety-critical applications, ensure full QC traceability.

- Combine harness assembly, busbar integration, and box-build under one partner to avoid coordination delays.

Displays, Sensors, and RF: Still Import-Heavy

What’s import-bound: Whether you work with consumer electronics or industrial products, TFTs, OLEDs, touchscreen modules, camera sensors, RF modules (WiFi, BLE, GNSS), and MEMS sensors, they are still heavily import-dependent. And even most electronic product development companies in India use these components rather than manufacturing them locally.

Founders Insight:

- Separate your display/RF procurement layer in the BOM from your core electronics.

- Order in quarterly cycles to manage customs and MOQ constraints.

- Pick EMS partners who are experienced in handling sensitive modules. This way, you can ensure you get proper bonding, ESD handling, and QC.

Testing, Packing, and Dispatch: Local Strength That’s Often Overlooked

What’s local: If managed under a single roof, then functional testing, burn-in, jig development, kitting, packaging, and dispatch can be done efficiently in India. What does this do? This will give you huge control over yield and timelines.

Founders Insight:

- Firstly, do not leave testing and packaging decisions for the end. What you want is a defined test strategy with your CM from the very start.

- You can plan for an integrated workflow, like: test → box build → labeling → dispatch. This will help you to keep the yield high and timelines right where you want them!

- If you are going for custom electronics enclosures, then make sure your packaging is designed to withstand Indian conditions. Whether it is humidity, shocks, or last-mile transport challenges, you can deal with them all!

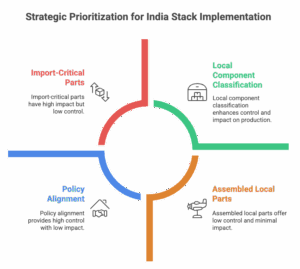

Strategic Playbook: How to Approach the India Stack

- Classify Your Bom By Geography, Not Just Part Number

You don’t just look at your BOM as a flat list of components. Instead, break it down and label them as local, assembled local, and import-critical. This simple classification will instantly highlight which parts are most likely to cause schedule slips and which ones you can control more tightly.

- Work With CM Partners Who Offer Sourcing Intelligence

A CM (Contract Manager) who builds from your BOM is a commodity! You can ask them questions like:

- Where are the parts coming from?

- Can you hold buffer stock for me?

- Are you proactive about suggesting alternatives before there’s a shortage?

The best electronic product development companies in India and EMS providers like Karkhana.io are not just reactive, but will flag risks before they become production delays.

- Forget 100% Localization.

Being in this industry for so long, we can say that the smartest founders don’t go “all-in” on local and global. For example, Import displays and RF modules, and localize enclosures, PCBA, harnesses, and packaging.

- Align Tooling And Fixture Strategy With Your Production Ramp

You must not make tooling decisions that shouldn’t be made in isolation, as they should match your volume plan.

For 10k+ units: Invest early in DFM, dedicated jigs, and modular test setups.

Under 2K units: Keep things flexible with manual stations and adjustable test benches.

- Be Realistic About Policy Timelines

Yes, PLI incentives are helpful, but they don’t instantly make every component sourceable in India. So whenever you plan, you can use these policies to amplify what’s already working in your supply chain. Basically, don’t build your entire localization plan on the promise of future capacity, but on what’s already scalable.

Final Word: The India Stack Isn’t a Checklist

Yes, India can produce a hardware product end-to-end. But the real advantage comes from how you combine local and global capabilities, match them to your product stage, and work with the right partners. Talking of the right partners, Karkhana.io is where you can put all your trust. Our teams are not asking “What’s available locally?”

They are asking:

- “What should I localize now?”

- “What needs to be integrated under one roof?”

- “Which electronic product development companies in India can orchestrate this with me?”

Because one thing to note here is that in hardware manufacturing, success isn’t just about building a BOM, but more about building a resilient strategy, cost-effective, and aligned with what India is best at!